High Frequency Biomedical Servo Hydraulic Dynamic Fatique Testing Machine

STANDARDS

ISO 7206-04, ISO 7206-06, ISO 7206-10 ISO 14801, ASTM E2368, ASTM F1264, ASTM F1541, ASTM F1717, ASTMF1264, ASTM F1800, ISO 14879, ASTM F2193,

ASTM F382, ASTM F543, ISO 12189, ISO 594, ASTM F384, ASTM F2346, ASTM F1614, DIN 50100, STM E4, DIN EN 15630

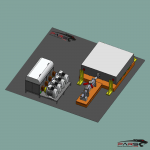

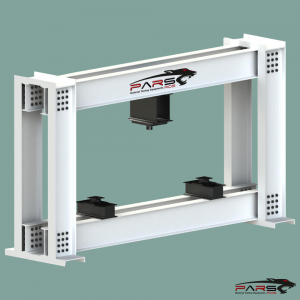

ParsRos High Frequency Servo Hydraulic Dynamic Fatique Testing Machine is manufactured in capacities between 10 kN and 1000 kN.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

| Product Code |

Product Description |

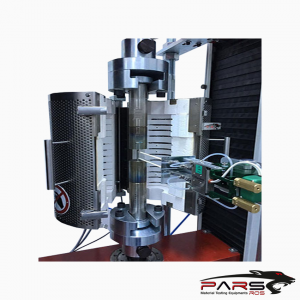

| PRS-HFBIOMTM | High Frequency Biomedical Servo Hydraulic Dynamic Fatique Testing Machine |

High Frequency Biomedical Servo Hydraulic Dynamic Fatique Testing Machine

STANDARDS

ISO 7206-04, ISO 7206-06, ISO 7206-10 ISO 14801, ASTM E2368, ASTM F1264, ASTM F1541, ASTM F1717, ASTMF1264, ASTM F1800, ISO 14879, ASTM F2193,

ASTM F382, ASTM F543, ISO 12189, ISO 594, ASTM F384, ASTM F2346, ASTM F1614, DIN 50100, STM E4, DIN EN 15630

GENERAL STANDARDS

ASTM F2267, ASTM F2077, ASTM F2346, ASTM F1717, ASTM F1789, ASTM F2193, ASTM F382, ASTM F897, ASTM F384, ASTM F1264, ASTM F543, ASTM F1635, ASTM F2313,

ASTM E2082, ASTM F564, ASTM F1820, ASTM F2009, ASTM F1800, ASTM F1829, ASTM F7206, ASTM E2368, ASTM F1541, ASTM F1800, ASTM F1664

ParsRos High Frequency Servo Hydraulic Dynamic Fatique Testing Machine is manufactured in capacities between 10 kN and 1000 kN.

*** Higher Capacities are manufactured on demand .

There is no limit related with with, depth and can be manufactured according to test requirements and customers wishes

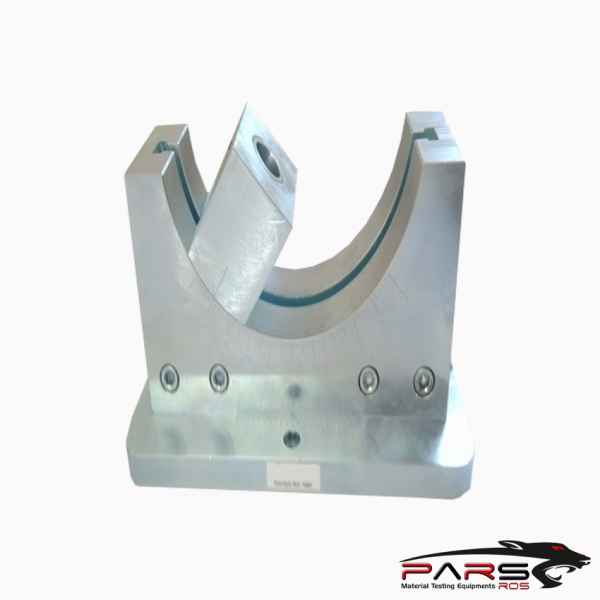

Load enhancer , grips , jaws and other test apparatus are manufactured by ParsRos Engineers according to related standards and test method .

Computer software is suitable for dynamic (cyclic) tests.

Thanks to software ; Load, elongation and strain adjustable tests can be done and user can enter unlimited parameters

The machine complies with international standards and manufactured from high quality components at the latest performance during manufacturing process .

The working voltage of the device is 400V three phase AC current and 50 / 60Hz. frequency range.

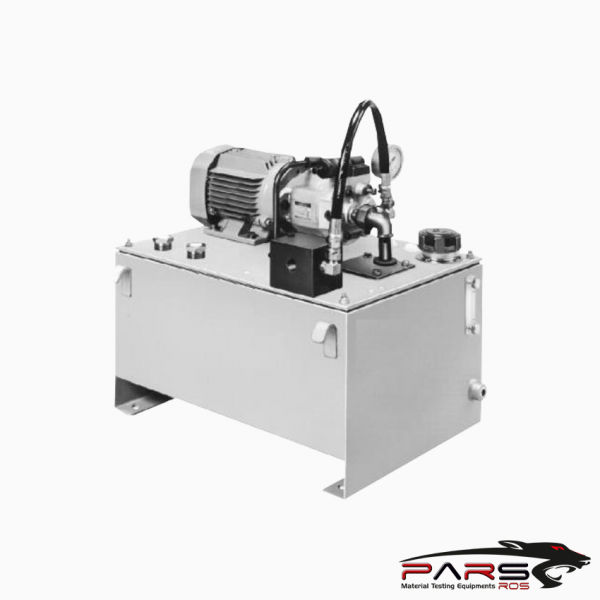

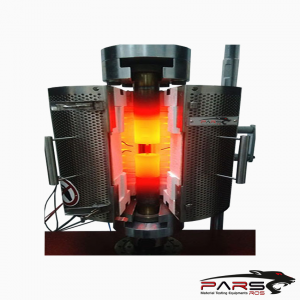

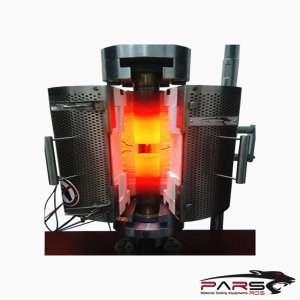

Radiators or heat exchangers are used in closed circuit cooling system to prevent overheating in hydraulic systems.

Temperature sensors that automatically stops the system against overheating

ParsRos Test Software recognizes the sensors in the system quickly and automatically and allows you to save time.

Software perform the test method and predefined configuration that are written by user

Parameters can be monitored via X-Y graphs on Computer screen in real time .

Thanks to sensors that are connected to the system ; position, load , instantaneous numerical values are achieved perfectly and provide the most accurate results.

Thanks to Dynamic test software , displacement , load and strain-stress controlled can be done

Cyclic fatigue tests can be done as both load-controlled and position-controlled

The software has its own calibration menu, calibration can be done by authorized engineer or technician.

FATIQUE TESTS

Fatigue testing is utilized for characterizing material properties and specimen behavior during cyclic loading.

Understanding the durability and limits of the device allows medical device manufacturers to bring safe and reliable products to market.

Given the complex regulation and high risk of medical device applications, fatigue testing must be stringently performed to the appropriate stress levels, sample size,

and standards according to well-defined test protocols.

PERFORMING TEST

Medical device fatigue testing focuses on the nominal stress required for failure after a number of cycles. Stress (S) is typically plotted on a log scale against the

number of cycles to failure (N), also known as S/N Fatigue Testing.

During an S/N fatigue test, the first sample group is tested at high peak stress (or strain in a variation of the test) where failure occurs after a low number of cycles.

Subsequent samples are tested at decreasing stress levels until astatistically significant number of samples do not fail in the specified number of cycles.

The fatigue threshold is the highest stress at which a runout (non-failure) occurs.

DETERMINING SAMPLE SIZE !!!

Determining the appropriate sample size is a balance between the number of tests needed for the highest level of statistical confidence and the cost of developing

the test specimens.

The number of samples needed depends on the standard deviation and desired levels of statistical significance.

Power analysis calculators are available online to help you determine the best sample size for your application.

Reviews (0)

TECHNICAL SPECIFICATIONS

Frequency/Amplitude: Sinusidial up to 100Hz

Force Dynamic Load Cell Accuracy: 0.5% (ISO 7500-1)

High precision fatigue rated loadcells.

Actuator: Hydrostatic Bearings

Piston Stroke: 100 or 150 mm ( High one avaible )

Crosshead movement can be provided by Hydraulic Cylinder

Stiffness: 100 Kn /mm over the total length

Electronic Controller by Doli (Made in Germany)

Controller Type: EDC 580

Data Acquisition : 5000 Hz, synchronously and real time ( 10khz avaible)

Test & Motion Standard Software and Dynapack Software

Grip designs according to specimen types.

Can be customized according to customer’s wishes and expectations.

****Different capacities are available

Leave a Reply