Servo Hydraulic Tensile Testing Machine ,600 kN

STANDARDS : ASTM E8M, ASTM E21, ASTM A 370, ASTM F519, ASTM B557, BS 18/1, BS 18/2, BS240, BS 1140,BS 1639, BS 2874, BS 3855, BS 4449, BS 4482, BS 4483,

BS 4545, ISO 5600 2740, ISO 5600 3325, ISO 5600 3928 EN 10002-1, EN 10002-5, EN 60855 , EN 845-3 ,DIN 50106, DIN 50111, DIN 50145, EN 6892 1

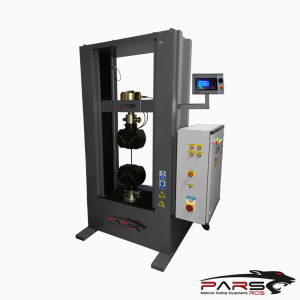

ParsRos Servo Hydraulic Tensile Testing Machines are high capacity systems with single test space andsuitable for tensile, compression, flexure tests on a wide range

of different materials such as round, flat and profilespecimens for quality control, product development, research or process development.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code |

Product Description |

| PRS-SHU-600 | Servo Hydraulic Tensile Testing Machine ,600 kN |

Servo Hydraulic Tensile Testing Machine ,600 kN

STANDARDS : ASTM E8M, ASTM E21, ASTM A 370, ASTM F519, ASTM B557, BS 18/1, BS 18/2, BS240, BS 1140,BS 1639, BS 2874, BS 3855, BS 4449, BS 4482, BS 4483,

BS 4545, ISO 5600 2740, ISO 5600 3325, ISO 5600 3928 EN 10002-1, EN 10002-5, EN 60855 , EN 845-3 ,DIN 50106, DIN 50111, DIN 50145, EN 6892 1

ParsRos Servo Hydraulic Tensile Testing Machines are high capacity systems with single test space andsuitable for tensile, compression, flexure tests on a

wide rangeof different materials such as round, flat and profilespecimens for quality control, product development, research or process development.

Testing systems for brittle materials such steel or fasteners requires high stiffness load frames that minimize the amount of deformation energy that is stored in

the frame.

*** Servo Hydraulic Tensile Testing Machine can be controlled via DOLI TEST & MOTION software that installed on the PC connected to the

Control Unit.

Servo-Hydraulic Universal Testing Machine can carry out tensile and yield, compression, flexure tests with load and displacement controls.

The main characteristics of Servo Hydraulic Tensile Testing Machine are;

Rigid 4 columns construction providing superior axial and lateral stiffness and precision alignment,

Closed-loop servo controlled hydraulic power pack for accurate test control,

High speed electronic control and data acquisition unit for accurate test results,

Single test space design with convenient vertical testing clearance,

Double acting servo-actuator mounted on top of the crossbeam

Actuator with anti-rotation system to prevent the natural tendency of the actuator to rotate.

Long piston stroke for the most convenient and easy adjustment and testing of different sample lengths,

Digital displacement transducer for the best positioning and measuring accuracy

Easy calibration procedure,

Servo Hydraulic Tensile Testing Machine – Doli Test & Motion Software for easy using,

Chrome plated columns for easy cleaning and longest life.

Wedge Actions Grips

Grip control system mounted on the frame

Compression platens or bending devices may be fixed directly into wedge grips,

Limit switch on the piston as well as the safety limit valves on the hydraulic system,

Servo-Hydraulic Universal Testing Machine is consisting of Load Frame, Advanced servo controlled automatic power pack, Electronic Control Unit and Material Testing

Software as standard.

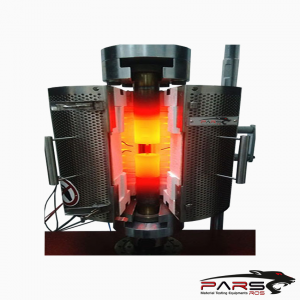

Depending to standards and requirements, Video extensometers, Automatic Extensometers, Clip-OnExtensometers, Flexure, Compression Test Apparatus,

High Temperature Cabinets and Multifunctional Remote Control Hand Set can be integrated on the Servo Hydraulic Universal Testing Machine.

Servo Hydraulic Tensile Testing Machine – FRAME

The double acting servo actuator, which is integrated on the upper crosshead, has a long piston stroke which makes vertical testing space accessible for easy and

efficient testing of different samples lengths.

Load cell for measuring the load is mounted between lower grip and base plate.

Displacement transducers that mounted in the piston are used for displacement measuring.

External Extensometers (Video extensometers, Long Travel Extensometers, Automatic Extensometers or Clip-On Extensometers) can be synchronously used for

displacement measurements if required.

Servo Hydraulic Tensile Testing Machine – OPTIONAL ACCESSORIES

Standard Extensometer

Clip-On Type Extensometers, 50 mm gauge length, 25 mm travel, 0,01 mm accuracy,

Clip-On Type Extensometers, 50 mm gauge length, 0,001 mm accuracy,

Clip-On Type Extensometers can measure the displacement directly from the specimens.

Automatic Extensometers

Automatic Extensometer, 10-300 mm gauge length, 0,1 μm accuracy.

These kind of extensometers are fully automatic computer-controlled and used for flat and round specimens with different measurement distance.

By means of high sensitivity it can even used on very delicate materials.

Servo Hydraulic Tensile Testing Machine – LOAD MEASUREMENT

By means of full bridge strain gage load cell mounted on the lower base

Robust design to withstand eventual overloads

High accuracy to allow for machine Class 1/ISO 7500- 1 from 2 to 100% of its nominal capacity

SAFETY

High repeatability and linearity design

Machines are designed to cover and follow with fidelity all the requirements demanded by standards and regulations.

An push buttom, mushroom type is located in front of the working frame for emergency stop.

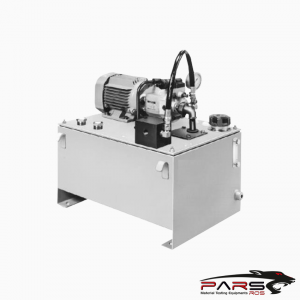

Servo Hydraulic Tensile Testing Machine – HYDRAULIC SYSTEM

Load application is made by means of a hydraulic piston, located within the machine frame.

To generate the pressure, a servo-hydraulic power unit, is comprised.

The high pressure power unit is tight fitted and pollution-proof, with very low noise.

Regulating the flow of hydraulic fluid (and hence the charging rate) is performed by means of a high performance servovalve mounted on a manifold

(hydraulic distributors).

The power pack assembly, manifold and servo valve is located inside of a work desk and rests on a set of four bumpers which prevent the transmission of vibrations

to the frame.

HYDRAULIC GRIPS

Hydraulically operated grips completely stop the possibility of sample sliding from the grips enabling for correct and definite strain measurements.

Hydraulic grips are very safe and user friendly.

Hydraulic grips come with grip sets for pulling 8 – 32 mm diameter cylinder samples.

The hydraulic grips has an independent hydraulic power unit with a working pressure of 400 bars.

*** Jaw faces for flat samples should be ordered separately.

Please Contach with Our Experts for Technical Information