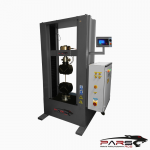

Horizantal Tensile Test Machine, 500 kN

STANDARDS : ASTM A931, ASTM D4268, EN 919, ISO 2307, OCIMF, EN 1891, EN 564, EN 566, EN ISO 1346:2004, EN ISO 2307:2010

ParsRos Servo Hydraulic Horizantal Tensile Test Machine has a very strong frame which allows a nominal force up to 10 MN.

The frame can have a length up to 40 m to perform test on real size specimens.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code |

Product Description |

| PRS-SRVHORTEN1000 |

Servo Hydraulic Horizantal Tensile Test Machine 500 kN |

Servo Hydraulic Horizantal Tensile Test Machine, 500 kN

STANDARDS : ASTM A931, ASTM D4268, EN 919, ISO 2307, OCIMF, EN 1891, EN 564, EN 566, EN ISO 1346:2004, EN ISO 2307:2010

ParsRos Servo Hydraulic Horizontal Tensile Test Machines have a very strong frame which allows a nominal force up to 10 MN.

The frame can have a length up to 40 m to perform test on real size specimens.

Standard tests can be performed with distance or force control.

The electronic controller accurately sticks to the set parameters during the test (speed, maximum load, holding time, strain values, etc.).

The experimental procedure is completely automated, and a lot of test modules are available to comply with a wide range of standard tests.

Some test modules even allow to perform dynamic tests to determine the service life of the specimens.

It is possible to perform dynamic tests with two different approaches: with a pre-programmed waveform (sine, rectangular, etc.) or with a specified path given by the

user.

Horizontal Tensile Test Machine – APPLICATIONS

Slings

Lashings

Chains

Cables

Synthetic fiber ropes

Natural fiber ropes

And many more…

Depending on the testing requirements, vertical test machines can also be used.

Horizontal test beds are widely used for the tensile test and destruction test of kinds of wire rope slings, electrical cable fittings, steel wire ropes, synthetic ropes,

chains, and shackles. It is an ideal testing machine for steel wires and ropes production, quality control and R&D lines.

They are popular in the industry of construction, building materials, metallurgical, transportation industry and energy resources industry and other units like research

units, universities, quality inspection center, commodity testing department, power center and so on.

Horizontal Tensile Test Machine – MAIN BODY

The main body is mainly composed of oil cylinder seat, piston, front portable clamping, rear portable clamping heads, crosshead and load cell etc.

Oil cylinder is installed on the cylinder seat; cylinder seat, steel plate welding frame and rear portable clamping heads are combined for the stress frame.

The specimen is placed between these two clamping heads to conduct the test.

Single cylinder rod offers impetus to the front portable clamping head and applied to specimen.

The rear portable clamping head is connected to the frame via locking pins

By the adjustment of locking pin, the backing moving crosshead could be moved along the track to adjust the test space by every 500mm.

LOADING SENSORS

Parsros Servo Hydraulic Horizantal Tensile Test Machine has the feature of connecting more than one loadcell.

Load accuracy is class 0,5. Can be increased load capacity to special applications. System identifies every loadcell automatically and calibration values are kept

its memory.

System closes to be exposed overload.

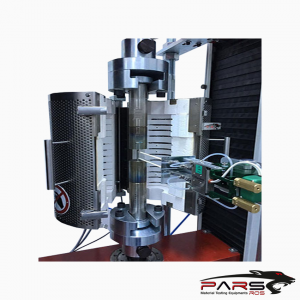

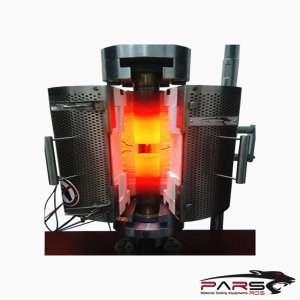

SERVO TECHNOLOGY

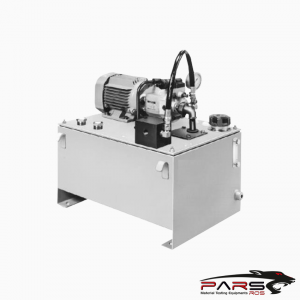

It comprises of servo control, electro-servo valve and servo actuator and sensor.

Servo control is featured with comparison, verification and amplifier of the system input signal.

Electro-Servo valve is featured with changing the current signal to hydraulic energy, which is the key component in the system and the servo actuator accepts the

hydraulic oil from servo valve to make action according to system requirement

| Model | PRS-SRVHORTEN1000 |

| Capacity | 500 Kn |

| Test class | 1 Grade |

| Load cell | 50 Ton Precision Load Cell (Class 1 in accordance with EN ISO 7500-1:2004) |

| Loading speed rate | 0.5KN/s~50kN/s |

| Position Sensor Resolution | 0.001mm |

| Piston stroke | 2000mm |

| Piston speed | 200-300mm/min |

| System Pressure | Max. 350 bar |

| Total frame length with cylinder | Approx. 8,5 m |

| Total weight (frame and cylinder ) | Approx. 4000 kg |

| System Software | Doli Test & Motion Software (Made in German) |

| Remote Controller | Doli RMC -7 |

| Actuator Speed | 0 – 300 mm/dk |

| Sample length | 3 meters |