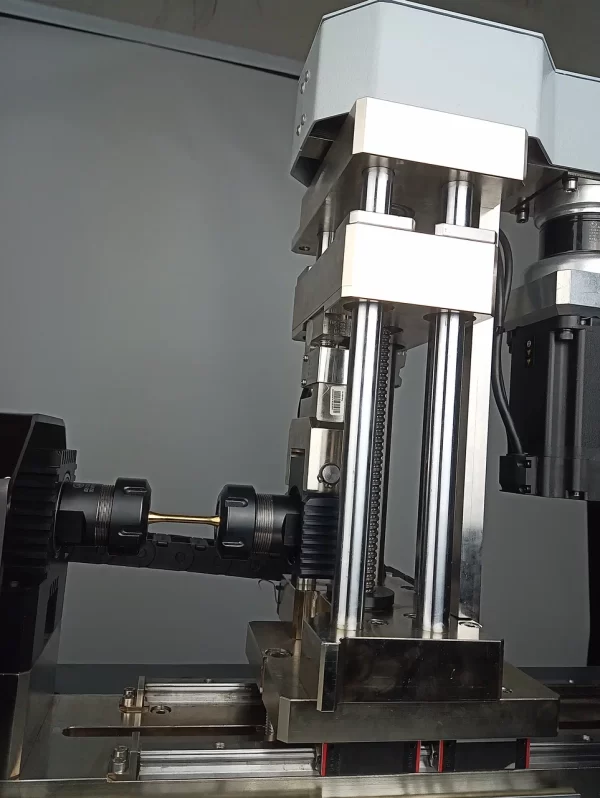

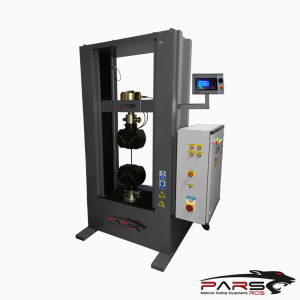

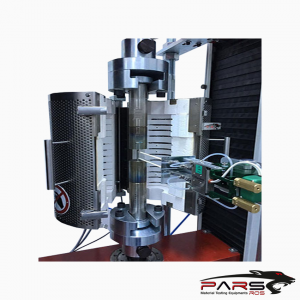

Rotary Bending Fatigue Testing Machine

ParsRos Rotary Bending Fatigue Testing Machines are suitable to test the fatigue strength of metals or other materials. These machines test the bending fatigue

limit of metals under the action of symmetrical, repeatedlyalternating bending force.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code |

Product Description |

| PRS-ROTBTMAC | Rotary Bending Fatigue Testing Machine |

Rotary Bending Fatigue Testing Machine

ParsRos Rotary Bending Fatigue Testing Machines are suitable to test the fatigue strength of metals or other materials. These machines test the bending fatigue

limit of metals under the action of symmetrical, repeatedlyalternating bending force.

Accordingly, the tension-compression fatigue limit and torsion fatigue limit can be determined by calculation according to experienced formula.

These systems are simple in structure, easy to operate, stable and reliable.

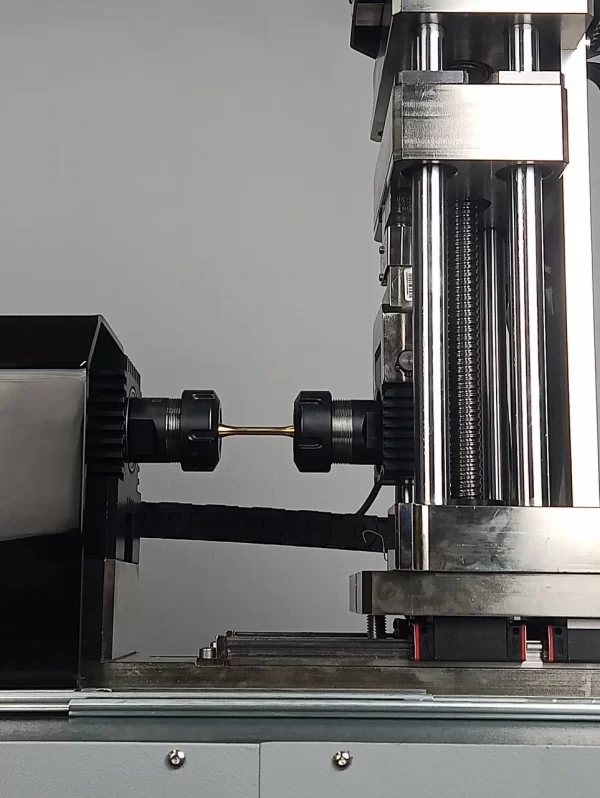

The machine design aims to implement load from two points on the rotating sample.

The sample functions as a simple rod and the load is loaded symmetrically at two points. When rotated half a turn, the stress-es in the clamping jaws are initially

reversed by placing the load on the sample. When the cycle iscompleted, stresses are generated in the opposite direction so that a complete bending stress cycle is

generated during a full cycle.

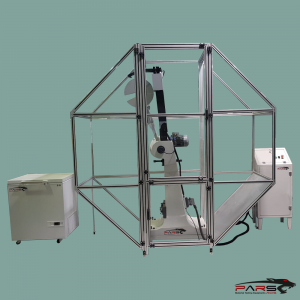

*** Our Rotary Bending Fatigue Test Machines are used in educational and research institutes to carry out fatigue tests of materials under bending and rotation.

Rotary Bending Fatigue Testing Machine – ROTATING BENDING FATIGUE TEST

Rotational moving parts and machine parts are subject to periodic fluctuating loads. Even if the dynamic load is well below the static load capacity, the cracks can

be suddenly spread after reaching a critical size and the size of the loads causing damage can be less than the tensile strength and / or yield strength of the material.

This load may cause the component to break after a long time due to material fatigue.

The fatigue strength of the components is determined in fatigue strength tests or endurance tests.

It shows the basic principles of fatigue strength testing and the creation of the Wöhler diagram (S-N curve).

Clean regular and simple operation means that the experimental sequence can be seen in all details and stages.

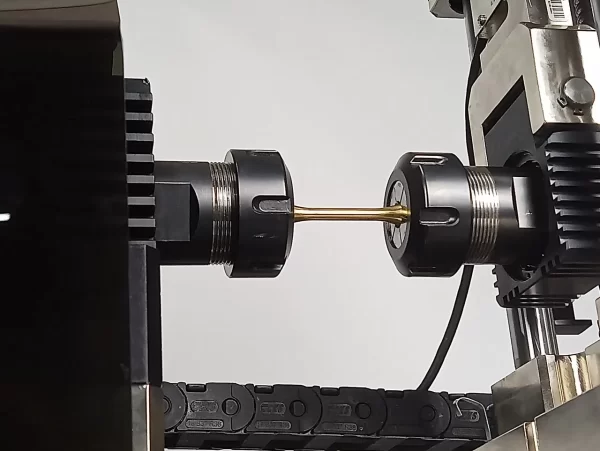

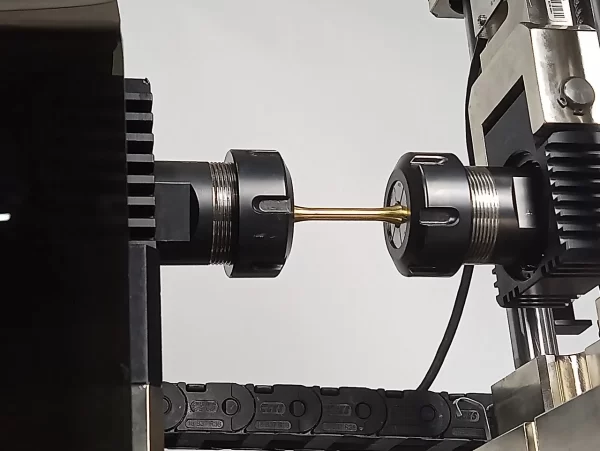

In the test, a cantilever mounted and rotating cylindrical sample is subjected to a single force.

The load on the sample corresponds to a cantilevered bend-ing beam.

The sample is directly subjected to bendingstress and the material is broken after a certain number of load cycles due to fatigue.

In the load application system, the necessary force is generated by means of a ball screw and a moving support.

The load amplitude can be adjusted continuously by means of a screw shaft or precision servo systems.

The non-contact encoder records the number of load cycles and displays them digitally.

The impulse for the encoder is provided by the inductive proximity sensor on the motor coupling. The encoder can also be used to measure speed.

When the sample breaks, the stop switch automatically stops the electric motor. A protective sheath protects against flying parts.

Samples with various fillet radii to illustrate the effect of the notch and the effect of the surfaces are included in the

| Engine | Standard 3-phase AC motor. (6000 rpm high speed motors as option.) |

| Ball Bearings | Bearings designed for high torsion resistance. |

| Vertical Weight | Calibrated loadcell controlled by stepper motor and screw shafts. (Servo motor and dead weight as option) |

| Sample Length | Customer needs can be determined in line with the requirements, the minimum length can be changed in kiln applications. |

| Sample Gripping system; | ER25 series Ø 1 – 16 mm ER32 series Ø 1 – 20 mm, |

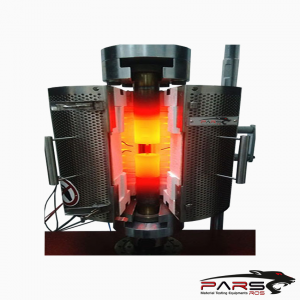

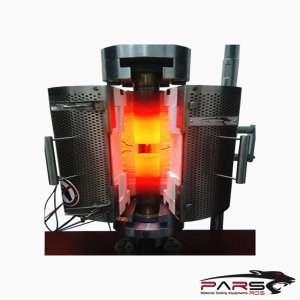

| Oven connection | Adjustable centering on x / y axes. |

| Power | 220 V, 50 Hz. 0.37 kW / For Oven 2 kW |

These systems are simple in structure, easy to operate, stable and reliable.

Compact table unit with constant bending, adjustable holders for specimens and the possibility to adjust the cooling temperature to -30 ° C,

Designed for testing at ambient temperature or with a high temperature oven up to 1000 ° C.