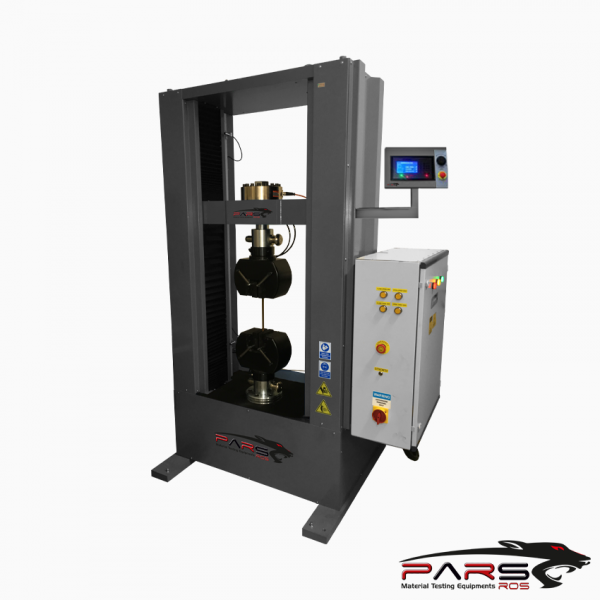

Electromechanical Tensile Test Machine, 100 kN

ParsRos Electromechanic Tensile Test Machines have high performance, accuracy, reliability and advanced user-friendly software and users delivers the most

accurate results in tests.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code |

Product Description |

| PRS-UETM-100 | Electromechanical Tensile Test Machine, 100 kN |

Electromechanical Tensile Test Machine, 100 kN

STANDARDS : ASTM E8M, ASTM E21, ASTM A 370, ASTM F519, ASTM B557, BS 18/1, BS 18/2, BS240, BS 1140, BS 1639, BS 2874, BS 3855, BS 4449, BS 4482, BS 4483,

BS 4545, ISO 5600 2740, ISO 5600 3325, ISO 5600 3928 EN 10002-1, EN 10002-5, EN 60855 , EN 845-3 ,DIN 50106, DIN 50111, DIN 50145

GENERAL SPECIFICATIONS

ParsRos Electromechanical Tensile Test Machines have high performance, accuracy, reliability and advanced user-friendly software and users delivers

the most accurate results in tests.

Electromechanical test systems with servo system running on high precision and efficiency, environmentally friendly oil-free, maintenance costs are low system.

The load frame is essentially composed of a base, columns, and moving crosshead. Most units have a single test space between the base and the crosshead.

These test systems are generally used in compressive, tensile and flexural test . Also they can be used for Disbonding, adhesion and cycle tests.

FEATURES OF THE MACHINE

±100 kN force capacity

Close Looped Controlled System

Equipped with servo motor and driver .They represent the high end solution.

Designed for static tensile, compression, bending, peeling or similar testing on a variety of materials

and components

Adjustable test area.

Adjustable upper crosshead position

Ergonomic setup and intuitive to use crosssshead

Floor type testing frame, easy set up to laboratory areas.

Designed to be used with the ParsRos accesories.

Compatible with a large range of grips, fixtures, chambers, video extensometers, automatic extensometers and other accessories

High technology loadcell that is class 0.5 according to ISO 7500-1.

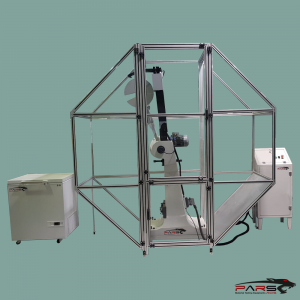

Safety cover is including (Optional )

Servo Engine and driver

Manaul or Hydraulic Wedge Action Grips

Jaws for round samples

Compression Platens ( Up & Down )

Flexural Test Assembly

Extensometers ( Optional )

Standard Extensometer

Clip-On Type Extensometers, 50 mm gauge length, 25 mm travel, 0,01 mm accuracy,

Clip-On Type Extensometers, 50 mm gauge length, 0,001 mm accuracy,

Clip-On Type Extensometers can measure the displacement directly from the specimens.

Automatic Extensometers

Automatic Extensometer, 10-300 mm gauge length, 0,1 μm accuracy.

These kind of extensometers are fully automatic computer-controlled and used for flat and round specimens with

different measurement distance. By means of high sensitivity it can even used on very delicate materials.

LOAD MEASUREMENT

By means of full bridge strain gage load cell mounted on the lower base

Robust design to withstand eventual overloads

High accuracy to allow for machine Class 1/ISO 7500- 1 from 2 to 100% of its nominal capacity