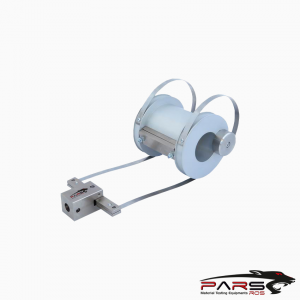

ASTM F38 Test Fikstürü

ASTM F38 provides a means of measuring the amount of creep relaxation of a gasket material at a predetermined time after a compressive stress has been applied.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ASTM F38 – Standard Test Methods for Creep Relaxation of a Gasket Material

ASTM F38 provides a means of measuring the amount of creep relaxation of a gasket material at a predetermined time after a compressive stress has been applied.

Test Method A—Creep relaxation measured by means of a calibrated strain gauge on a bolt.

Test Method B—Creep relaxation measured by means of a calibrated bolt with dial indicator.

ASTM F38 / Significance and Use

These test methods are designed to compare related materials under controlled conditions and their ability to maintain a given compressive stress as a function

of time.

A portion of the torque loss on the bolted flange is a result ofof the bolts, distortion of the flanges, and vibration; therefore, the results obtained should be correlated

with field results.

These test methods may be used as a routine test when agreed upon between the consumer and the producer.

NOTE 1—Test Method B was developed using asbestos gasket materials and at issuance substantiating data were not available for other gasket materials.

ASTM F38 / Apparatus

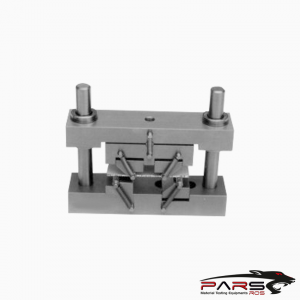

Test Method A

1- Strain Indicator.

2- Timer.

3- Relaxometer,4composed of two platens, upper and lower; a bolt, with mounted strain gauge; and a thrust bearing.

Strain Gauges,6120 Ω resistance with a gauge factor of 2.0 6 0.10 %.

The gauges shall be mounted to indicate tensile strain and positioned to compensate for torque, temperature, and bending.

The gauges shall be mounted on the small diameter of the bolt about 50.8 mm (2 in.) from the head.

The bolt with mounted strain gauges must be calibrated.

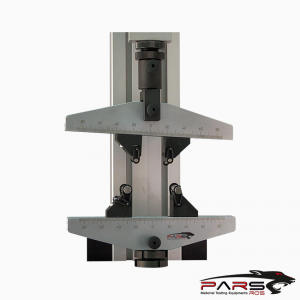

Test Method B

Relaxometer, Platen Assembly composed of two platens, specially drilled and calibrated bolt, washer and nut composed of Specification A193/A193M

Grade B7 or Specification B637 Grade UNS N07718 or other alloys of construction that would satisfy the calibration procedure (see Annex) for the test temperature

Dial Indicator Assembly, composed of an adaptor body, floating pin, set screw, and dial indicator.

Dial indicator should have graduations of 0.0025 mm (0.0001 in.) or smaller.

Box End Wrench—9⁄16 in., Qty. 2.

ASTM F38 / Summary of Test Methods

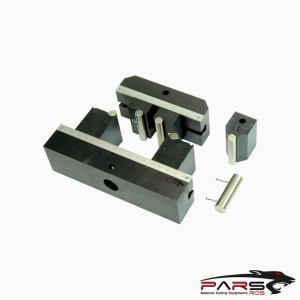

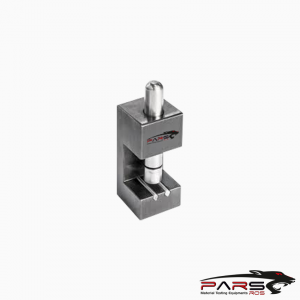

In both test methods the specimen is subjected to a compressive stress between two platens, with the stress applied by a nut and bolt.

In Test Method A, normally run at room temperature, the stress is measured by a calibrated strain gauge on the bolt.

In running the test, strain indicator readings are taken at intervals of time, beginning at the loading time, to the end of the test.

The strain indicator readings are converted to percentages of the initial stress which are then plotted against the log of time in hours.

The percentage of initial stress loss or relaxation can be read off the curve at any given time, within the limits of the total test time.

In Test Method B, run at room or elevated temperatures, the stress is determined by measuring the change in length of the calibrated bolt with a dial indicator.

The bolt length is measured at the beginning of the test and at the end of the test; from this the percentage of relaxation is calculated

*** Before conducting ASTM F38 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın