ASTM F2378 Test Fikstürü

ASTM F2378 covers a means of evaluating the sealing properties of sheet, composite, and solid form-in-place gasket materials

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM F2378 – Standard Test Method for Sealability of Sheet, Composite, and Solid Form-in-Place Gasket Materials

ASTM F2378 covers a means of evaluating the sealing properties of sheet, composite, and solid form-in-place gasket materials (see Classification F104 or F868)

at room temperature, and may be used for fluid (gas or liquid) leak rate measurements.

It utilizes relatively short hold times and is not intended to predict long-term performance in application.

This test method is suitable for evaluating the sealing characteristics of a gasket material under different press loads by measuring the leakage rate.

This test method may be used as an acceptance test when the producer and user have agreed to specific test conditions for the following parameters:

(1) Test medium,

(2) Internal pressure of the medium,

(3) Press load onthe gasket specimen, a

(4) The surface finish of the platens.

ASTM F2378 / Significance and Use

This test method is designed to compare sealing char- acteristics of gasket materials under controlled conditions by providing a precise measure of leakage rate at

different press loads up to 32 MPa (4640 psi).

This test method is suitable for measuring leakage rates from 0.1 mL/min to as high as 5 L/min for gases.

This test method evaluates leak rates after time periods (typically 30 min) that result in a steady state leakage rate condition.

Holding gasket materials under load and internal fluid pressure until steady state is achieved is required to obtain reproducible results.

If the fluid being used in the test causes changes, such as swelling, in the gasket material, it may affect results and diminish repeatability.

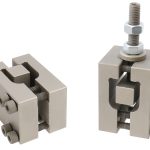

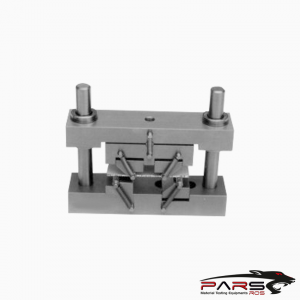

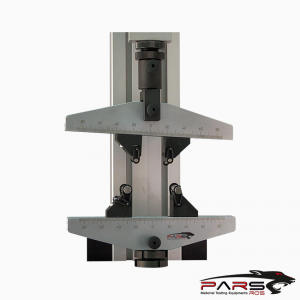

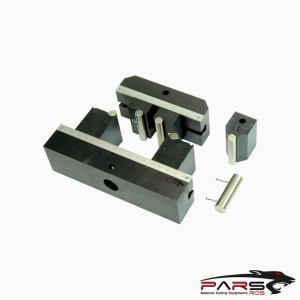

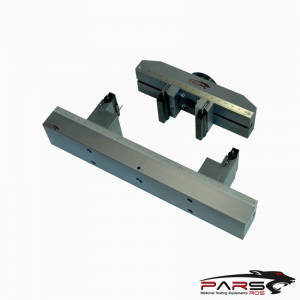

ASTM F2378 / Apparatus

The apparatus shall consist of a press frame (for example, one rated at 225 kN (25 tons) or greater), with well-aligned platens, or a ball-jointed platen against

a fixed platen.

The platens shall be aligned parallel within 2 % of the test specimen nominal thickness.

ASTM F2378 / Calibrated Hydraulic System, or load cells may be used to monitor the load.

Hydraulic system should have a load setting and controlling system with an accuracy of 64 MPa (60 psi) or 1 % of the target load.

ASTM F2378 / Calibrated Regulator and Gages, to monitor internal gas pressure or gas pressure over liquid.

Test pressure should be monitored and controlled with an accuracy of 640 kPa (6 psi).

ASTM F2378 / Temperature and Pressure (10.35 MPa (1500 psi))

ASTM F2378 / Corrected Mass Flow Meters, to monitor gas flow (leakage) from the gasket fixture.

Typically multiple mass flow meters are piped parallel to the flow with only the most sensitive meter for the flow conditions valved to the leakage stream.

For example, 0-10, 0-100, and 0-1000 mL/min mass flow meters may all be accurate to 0.25 %, but the former will measure a 1 mL/min-leak 100 times more

accurately than the latter.

Other leak measurement devices may be used as agreed upon between the producer and the user.

Mass flow meters should have an accuracy of 61 % of full scale or better.

ASTM F2378 / Pressure Control Regulators, to limit variation and alarm, low pressure may be used at the discretion of the users, producers, or both.

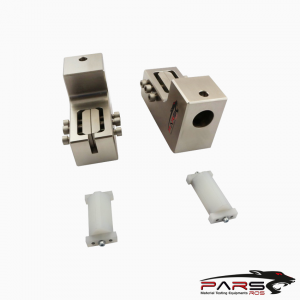

ASTM F2378 / Platens, hardened and machined with either a serrated concentric or serrated spiral finish having a resultant surface finish as agreed upon

between the producer and user.

Platens should be a minimum of 25 mm (1.0 in.) thick.

Platens, shall be fitted with an OD rubber seal to contain the leaking gas.

The platens shall be suitably drilled to accept the high-pressure gas inlet fitting and to permit a flow of the pressurizing fluid to fill the annulus of the test specimen,

and to allow the pressure gage to be connected.

The outlet leaking fluid fitting shall be drilled to collect the fluid outside of the test specimen OD and within the rubber seal.

The leak collection depends on the rubber seal.

The load to seal the rubber seal shall be compensated so that the target press load is achieved within the tolerance of 6.2.

The center volume can be fitted with a solid plug to minimize internal volume and aid in platen alignment.

The recess in the bottom of the fixture is intended to retain circular alignment with the hydraulic press.

ASTM F2378 / Summary of Test Method

This test method utilizes a test specimen compressed in increasing stages between the surfaces of two flat steel platens.

After the specified press load is applied, fluid (typically nitrogen) is introduced into the center of the annular gasket compressed between platens, and a pressure

of 4 MPa (580 psi) is applied.

The fluid leak rate is measured.

The fluid pressure is relieved and the press load is increased to the next level.

The fluid pressure is reapplied and the leak rate measured again.

The cycle is repeated 5 times until a final press load of 32 MPa (4640 psi) is achieved.

Other press loads, internal pressures, pressurizing fluids, and number of cycles can be used as agreed upon between the producer and the user.

All variations from the standard requirements must be reported with the test results.

The fluid leak rate is measured by mass flow meters located downstream from the gasket test fixture.

Other means of leak measurement also may be used and would depend upon the test fluid, the leak rate, and the accuracy required as agreed upon between

the producer and the user.

*** Before conducting ASTM F2378 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.