ASTM D829 Test Fikstürü

ASTM D829 measures the (wet) tensile breaking strength of paper, paper products, and paperboard (excluding corrugated board) when saturated with water.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ASTM D829 Standard Test Methods for Wet Tensile Breaking Strength of Paper and Paper Products

ASTM D829 measures the (wet) tensile breaking strength of paper, paper products, and paperboard (excluding corrugated board) when saturated with water.

ASTM D829 is intended for use with papers and paper products that will be subjected to stress while wet during processing or use, including but not limited to

tissue products, papers used in map-making, photography and blue prints, bags, and food wraps.

Test methods are described; one for samples that are able to be handled while wet without damage, and one for samples, such as tissue, that are easily damaged or

impossible to handle while wet

ASTM D829 / Summary of Test Methods

These test methods consist of two test methods as follows:

Test Method A—Immersion Wetting Procedure

Test Method B—Finch Procedure

In Test Method A, a test specimen is immersed in distilled water at 23°C for the time period required to reach saturation as defined in these test methods that

may be as long as 24 h.

After saturation, the specimen is tested as described in Test Method D 828.

Test Method A is suited for papers that can be handled wet without damage, including papers that retain a high percentage of their original (dry) strength when

wet such as photographic, map, and blueprint papers, food wraps, and some bags.

In Test Method B, a test specimen is saturated with water in a Finch wet strength device and then tested as described in Test Method D 828.

Test Method B is suited for papers that are highly absorbent, easily damaged when wet, or both, such as tissue paper, particularly

ASTM D829 / Apparatus

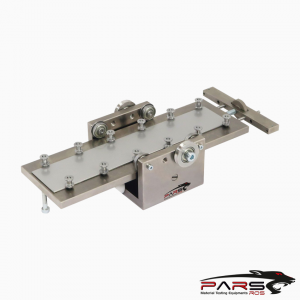

Tensile Tester

A tensile tester meeting the specifications found in Test Method D 828 is suitable for these test methods

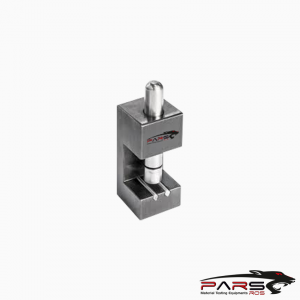

Finch Wet Strength Device

A device allowing a specimen to be saturated with water and then tested without further handling. Required for Test Method B only.

Two styles are available. Either one complies with these test methods.

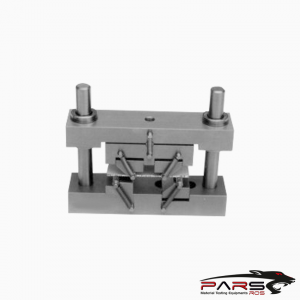

ASTM D829 / Finch Wet Strength Device (Older Style)

A wet strength device consisting of an inverted stirrup about 38 mm (1.5 in.) in width and about 76 mm (3 in.) in length, made of metal strap by which a horizontal

rod about 28 mm (1.1 in.) in length and 5 6 0.05 mm (0.188 6 0.002 in.) in diameter is supported.

Between the straps and under the horizontal rod is a small, vertically movable container for holding water or other liquid.

The liquid container locks in its uppermost position, so that the horizontal rod is then immersed in the liquid to a depth of at least 19 mm (0.75 in.).

A thin metal tang forming the lower part of the inverted stirrup permits it to be fastened in the lower clamp of a tension testing machine.

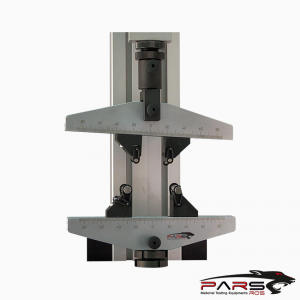

ASTM D829 / Finch Wet Strength Device (Newer Style)

A wet strength device consisting of a stainless steel casting of approximately 110 mm (4.375 in.) total length.

A thin bottom tang about 25 mm (1 in.) in width and 19 mm (0.75 in.) in length comprises the bottom portion of the casting.

The upper portion of the casting consists of a rod of about 5 6 0.05 mm (0.188 6 0.002 in.) in diameter about 26 mm (1.03 in.) in length affixed and supported

as part of the casting such that it extends freely in a direction perpendicular to the long direction of the casting approximately 44 mm (1.75 in.) below the top

of the casting.

A vertically moving liquid container is fastened to the body of the casting and is free to move such that when the liquid container is filled with fluid,

it may be moved to a position such that the horizontal rod is immersed to a depth of at least 19 mm (0.75 in.).

The main difference between the old and new style Finch wet strength devices is that the new style provides easier, direct access to the rod under which the

specimen must be inserted, thus specimen loading is simpler, easier, and more rapid.

Finch wet strength devices similar in design to that described before are available with longer rods and larger fluid containers for use with specimens wider than

1 in. (25.4 mm).

The rod of the Finch wet strength device must always be at least as long as the width of the test specimen

*** Before conducting ASTM D829 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

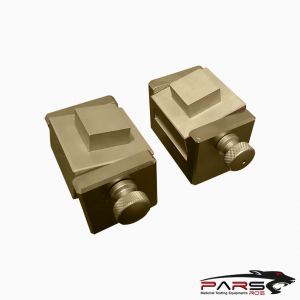

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın