ASTM D7269 – Tensile Testing of Aramid Yarns

ASTM D7269 – These test methods cover the tensile testing of aramid yarns, cords twisted from such yarns, and fabrics woven from such cords.

The yarn or cord may be wound on cones, tubes, bobbins, spools, or beams; may be woven into fabric; or may be in some other form.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ASTM D7269 – Tensile Testing of Aramid Yarns

ASTM D7269 – These test methods cover the tensile testing of aramid yarns, cords twisted from such yarns, and fabrics woven from such cords.

The yarn or cord may be wound on cones, tubes, bobbins, spools, or beams; may be woven into fabric; or may be in some other form.

The methods include testing procedure only and include no specifications or tolerances.

This standard includes the following test methods:

| Breaking Force |

| Breaking Tenacity |

| Breaking Toughness |

| Elongation at Break |

| Force at Specified Elongation (FASE) |

| Linear Density |

| Modulus |

| Stress at Break |

| Work-to-Break |

ASTM D7269 – Significance and Use

The levels of tensile properties obtained when testing aramid yarns and cords are dependent on the age and history of the specimen and on the specific conditions

used during the test.

Among these conditions are rate of stretching, type of clamps, gauge length of specimen, temperature and humidity of the atmosphere, rate of airflow across the

specimen,and temperature and moisture content of the specimen.

Testing conditions accordingly are specified precisely to obtain reproducible test results on a specific sample.

Because the force-bearing ability of a reinforced product is related to the strength of the yarn or cord used as a reinforcing material, breaking force is used in

engineering calculations when designing various types of textile reinforced products.

When needed to compare intrinsic strength characteristics of yarns or cords of different sizes or different types of fiber, breaking tenacity is very useful because,

for a given type of fiber, breaking force is approximately proportional to linear density.

** Elongation of yarn or cord is taken into consideration in the design and engineering of reinforced products because of its effect on uniformity of the finished

product and its dimensional stability during service.

** The FASE is used to monitor changes in characteristics of the textile material during the various stages involved in the processing and incorporation of yarn

or cord into a product.

** Modulus is a measure of the resistance of yarn or cord to extension as a force is applied.

It is useful for estimating the response of a textile reinforced structure to the application of varying forces and rates of stretching.

Although modulus may be determined at any specified force, initial modulus is the value most commonly used.

** Work-to-break is dependent on the relationship of force to elongation.

It is a measure of the ability of a textile structure to absorb mechanical energy. Breaking toughness is work-to-break per unit mass.

** It should be emphasized that, although the preceding parameters are related to the performance of a textile-reinforced product, the actual configuration

of the product is significant.

Shape, size, and internal construction also can have appreciable effect on product performance.

It is not possible, therefore, to evaluate the performance of a textile reinforced product in terms of the reinforcing material alone.

** If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine

if there is a statistical bias between them, using competent statistical assistance.

As a minimum, test samples should be used that are as homogeneous as possible, that are drawn from the material from which the disparate test results were

obtained, and that are randomly assigned in equal numbers to each laboratory for testing.

Other materials with established test values may be used for this purpose.

The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series.

If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

*** Before conducting ASTM D7269 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

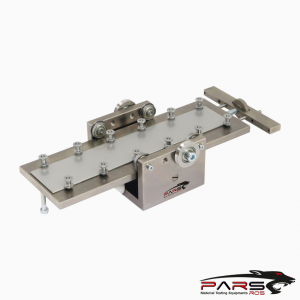

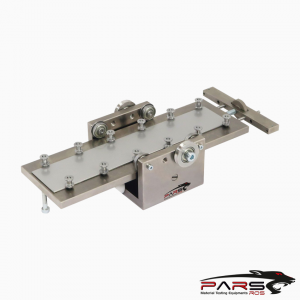

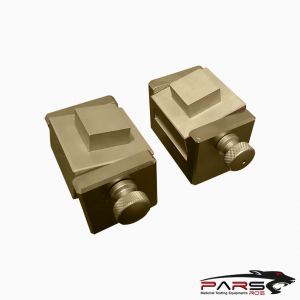

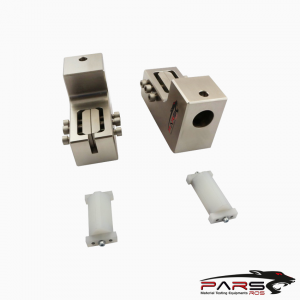

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that are

accurate and repeatable.

Değerlendirmeler (0)

TEKNİK ÖZELLİKLER

Teknik Detaylar İçin Lütfen Bizimle İletişime Geçiniz

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Bir yanıt yazın