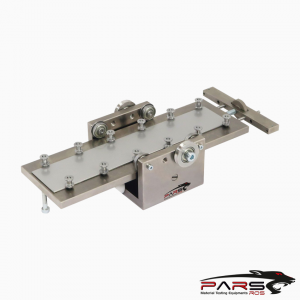

ASTM D5804 Test Fikstürü

ASTM D5804 provides a quick reliable means to measure the zero-span tensile strength of a randomly oriented specimen of fibers when dry.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D5804 Standard Test Methods for Zero-Span Tensile Strength (“Dry Zero-Span Tensile”)

ASTM D5804 provides a quick reliable means to measure the zero-span tensile strength of a randomly oriented specimen of fibers when dry.

Similar procedures for determining the zero-span tensile strength of a randomly oriented specimen of fibers when wet are found in Test Method D 5803.

In this test method, the fibers are tested as a handsheet produced using a standardized procedure such as TAPPI T 205.

While testing is possible on finished paper materials, information on fiber quality from intermediate steps in the pulping or paper making process, or both,

is frequently more useful for improving finished paper quality or improving fiber utilization of, for example, recycled fibers, or fibers subjected to new pulping,

bleaching, or finishing processes.

The modifications of the procedure described in this test method required for testing finished paper is straightforward; however, testing must be done in the two

principle directions of the sheet, as required in Test Method D 828, since the finished paper or paperboard will generally have non-random fiber orientation,

resulting in different strength properties in the two principle directions of the finished sheet.

Testing of sheets having a grammage greater than 100 g/m2 , which includes some paper materials described as paper and many paperboards, is difficult

because of problems associated with clamping of individual fibers as the number of fibers per unit area increases.

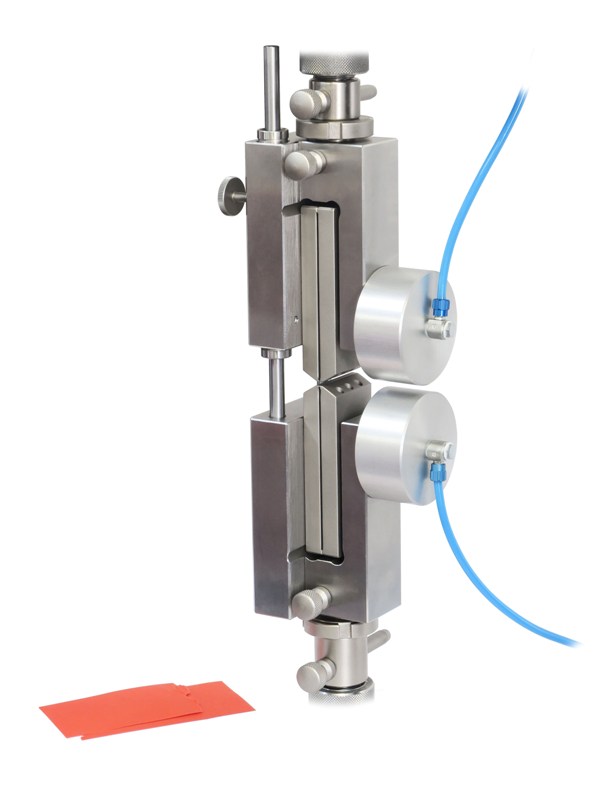

ASTM D5804 Apparatus

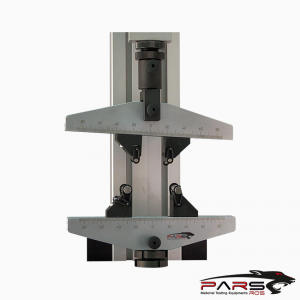

Zero-Span Jaws, comprised of two adjacent, spatially aligned clamping jaws in initial intimate contact (“zero-span”), which reliably and reproducibly exert

a very high, optimum, and uniform clamping pressure on fibers in a test specimen.

The essential elements that must be incorporated into any zero-span tester

ASTM D5804 Testing and Measuring System

The apparatus shall provide the means to exert and measure an in-plane tensile force within the clamped fiber test strip and to increase this force at a

controllable rate until tensile failure occurs.

In cases where a combined instrument providing zero-span jaws incorporated into an integrated measuring and recording system

the means for exerting in-plane tensile force incorporated in that instrument complies with

The controlled increase in tensile force shall be at a rate of 25 6 2 N/s/cm of jaw width, unless reported to the contrary as a deviation from this test method

in the report.

In cases where separate zeros-span jaws the means of incorporating in-plane tensile force shall be a constant rate of elongation type tensile tester complying with

Test Method D 828, having a range of at least 20 kg (45 lb), and adjusted to apply a gradually increasing load so as to break the specimen

A measuring system is used to record the tensile load carried by the specimen at the moment of the tensile failure. 5

There are no special requirements for the electronic measurement system beyond that generally found in equipment complying with Test Method D 828 or

similar measurement systems incorporated in self-contained zero-span tensile testers.

*** Before conducting ASTM D5804 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

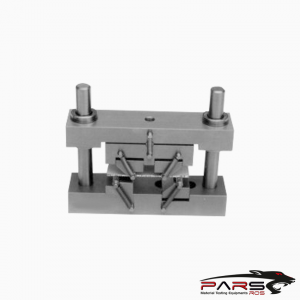

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.