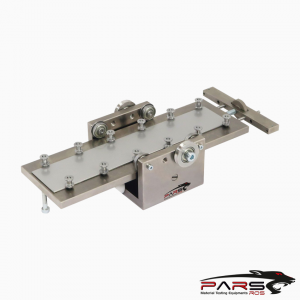

ASTM D5034 Test Fikstürü

ASTM D5034 covers the grab and modified grab test procedures for determining the breaking strength and elongation of most textile fabrics.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D5034 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

ASTM D5034 covers the grab and modified grab test procedures for determining the breaking strength and elongation of most textile fabrics.

Provisions are made for wet testing.

The grab test procedure is applicable to woven, nonwoven, and felted fabrics, while the modified grab test procedure is used primarily for woven fabrics.

This test method is not recommended for glass fabrics, or for knitted fabrics and other textile fabrics which have high stretch (more than 11 %).

Summary of Test Method

100-mm (4.0-in.) wide specimen is mounted centrally in clamps of a tensile testing machine and a force applied until the specimen breaks.

Values for the breaking force and the elongation of the test specimen are obtained from machine scales, dials, autographic recording charts, or a computer

interfaced with the testing machine.

ASTM D5034 describes procedures for carrying out fabric grab tensile tests using two types of specimens and three alternative types of testing machines.

For reporting, use the following identification system of specific specimen and machine combinations.

ASTM D5034 – Type of specimen:

G—Grab

MG—Modified grab

Type of tensile testing machine:

Constant-rate-of-extension (CRE)

Constant-rate-of-load (CRL)

Constant-rate-of -traverse (CRT)

ASTM D5034 – Significance and Use

The grab test procedure in this test method for the determination of breaking force and elongation is considered satisfactory for acceptance testing of

commercial shipments of most woven or nonwoven textile fabrics, and the modified grab test procedure is considered satisfactory for acceptance testing of

commercial shipments of most woven textile fabrics, since the procedures have been used extensively in the trade for acceptance testing.

In case of disagreement arising from differences in reported test values when using this test method for acceptance testing of commercial shipments,

This test method is not recommended for knitted fabrics because of their high stretch.

Some modification of technique may be necessary for any fabric having a strength in excess of 200-N/cm (1140-lb/ in.) width.

Special precautionary measures are provided for use when necessary for strong fabrics.

All of the procedures are applicable for testing fabrics either conditioned or wet.

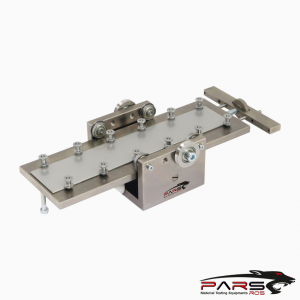

ASTM D5034 – Apparatus

Tensile Testing Machine, of the CRE, CRL, or CRT type conforming to Specification D76, with respect to force indication, working range, capacity, and

elongation indicator, and designed for operation at a speed of 300 6 10 mm/min (12 6 0.5 in./min); or, a variable speed drive, change gears, or interchangeable

weights as required to obtain the 20 6 3-s time-to-break

ASTM D5034 – Clamps and Jaw Faces—Each jaw face shall be smooth, flat, and with a metallic, or other agreed upon, gripping surface.

The faces shall be parallel and have matching centers with respect to one another in the same clamp and to the corresponding jaw face of the other clamp.

For grab tests, each clamp shall have a front (or top) jaw face measuring 25 6 1 mm (1.0 6 0.02 in.) perpendicular to the direction of the application of the force,

and not less than 25 nor more than 50 mm (1.0 nor more than 2.0 in.) parallel to the direction of the application of the force

(Note 2). The back, or bottom, jaw face of each clamp shall be at least as large as its mate. Use of a larger face for the second jaw reduces the problem of front and

back jaw face misalignment.

NOTE 2—Front (or top) faces measuring 25 by 50 mm (1.0 by 2.0 in.) will not necessarily give the same value as 25 by 25-mm (1.0 by 1.0-in.) faces.

For many materials, the former are preferable because of the larger gripping area which tends to reduce slippage.

While both sizes of gripping surface are permitted, the face sizes used must be the same for all samples in the test and must be recorded in the report.

For modified grab tests, the top (or front) jaw faces shall measure 25 by 50 mm (1.0 by 2.0 in.) or more, with the longer dimension parallel to the direction

of load application.

The bottom (or back) jaw faces shall measure 50 by 50 mm (2.0 by 2.0 in.)

*** Before conducting ASTM D5034 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

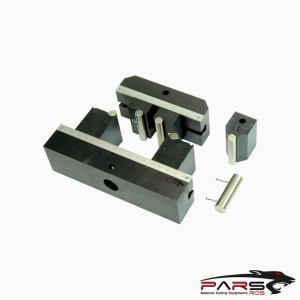

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.