ASTM D2344 – Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

Short Beam Shear Testing

ASTM D2344 – This test method determines the short-beam strength of high-modulus fiber-reinforced composite materials.

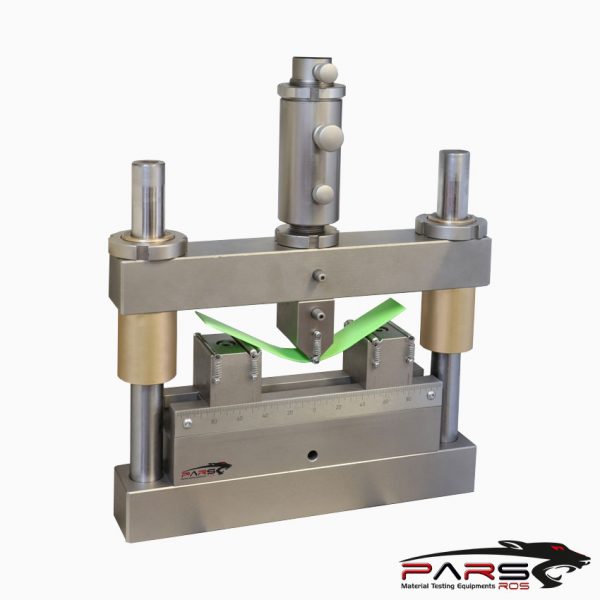

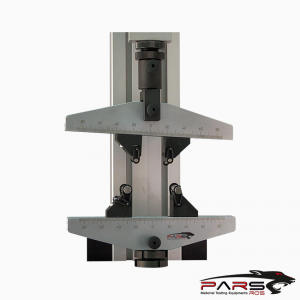

The specimen is a short beam machined from a curved or a flat laminate up to 6.00 mm [0.25 in.] thick.

The beam is loaded in three-point bending.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D2344 – Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

ASTM D2344 – Short Beam Shear Testing

ASTM D2344 – This test method determines the short-beam strength of high-modulus fiber-reinforced composite materials.

The specimen is a short beam machined from a curved or a flat laminate up to 6.00 mm [0.25 in.] thick. The beam is loaded in three-point bending.

Application of this test method is limited to continuous- or discontinuous-fiber-reinforced polymer matrix composites, for which the elastic properties are balanced

and symmetric with respect to the longitudinal axis of the beam.

Significance and Use

In most cases, because of the complexity of internal stresses and the variety of failure modes that can occur in this specimen,

it is not generally possible to relate the short-beam strength to any one material property.

However, failures are normally dominated by resin and interlaminar properties, and the test results have been found to be repeatable for a given specimen geometry,

material system, and stacking sequence (4).

Short-beam strength determined by this test method can be used for quality control and process specification purposes.

It can also be used for comparative testing of composite materials, provided that failures occur consistently in the same mode (5) .

This test method is not limited to specimens within the range specified in Section 8, but is limited to the use of a loading span length-to-specimen thickness

ratio of 4.0 and a minimum specimen thickness of 2.0 mm [0.08 in.].

The data can be used for research and development purposes concerned with interply strength, or prove useful in comparing composite materials.

*** Before conducting ASTM D2344 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

Test procedure: The thickness and width of the test specimen are measured before conditioning.

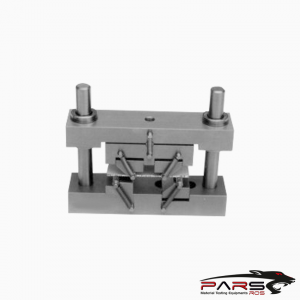

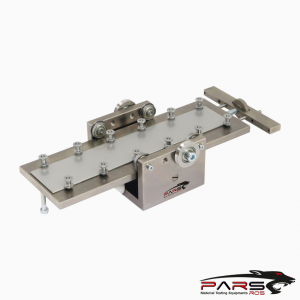

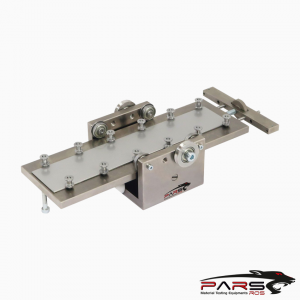

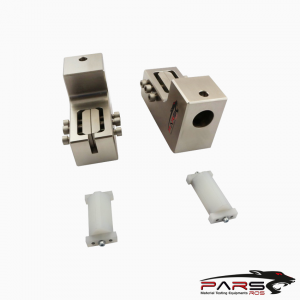

The specimen is placed on a horizontal shear test fixture so that the fibers are parallel to the loading nose.

The loading nose is then used to flex the specimen at a speed of .05 inches per minute until breakage.

The force is then recorded. Calculations are performed to determine shear strength.

Specimen size: The test specimens are machined from flat, finished composites.

Data: Shear strength = 0.75 x breaking load width x thickness

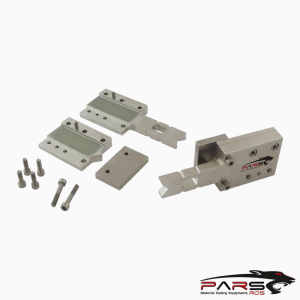

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that are

accurate and repeatable.

Teknik Detaylar İçin Lütfen Bizimle İletişime Geçiniz

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations