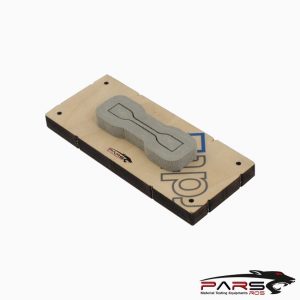

ISO 130503-2 Test Fixture

ISO 130503-2 provides standard testing procedures for evaluating proppants used in hydraulic fracturing and gravel-packing operations.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

ISO 130503-2 Petroleum and Natural Gas Industries — Completion Fluids and Materials

Part 2: Measurement of Properties of Proppants Used in Hydraulic Fracturing and Gravel-Packing Operations

ISO 130503-2 provides standard testing procedures for evaluating proppants used in hydraulic fracturing and gravel-packing operations.

NOTE “Proppants” mentioned henceforth in this part of ISO 13503 refer to sand, ceramic media, resin-coated proppants, gravel-packing media and

other materials used for hydraulic fracturing and gravel-packing operations.

The objective of this part of ISO 13503 is to provide a consistent methodology for testing performed on hydraulic fracturing and/or gravel-packing proppants.

ISO 130503-2 – Proppant Crush-Resistance Test

Crush Resistance Tests are conducted on samples to determine the amount of proppant crushed at a given stress.

Description

This test is useful for determining and comparing the crush-resistance of proppants.

Tests are conducted on samples that have been sieved so that all particles tested are within the specified size range.

The amount of proppant material crushed at each stress level is measured.

Evaluation of test results should provide indications of the stress level where proppant crushing is excessive and the maximum stress to which the proppant

material should be subjected.

Equipment and Materials

The following equipment and materials are required for conducting the proppant crush-resistance test:

Hydraulic load frame, with the capacity to apply the load required for accomplishing the stress levels up to 103 MPa (15 000 psi).

The load frame shall have platens that can be maintained parallel during application of load to the cell.

The load frame shall be calibrated at least annually and after all major repairs, to ensure that stress measurements are accurate to within 5 %, or an independent

calibrated load-measuring device should be used when the load is applied to the cell.

The stress shall never exceed the target value by more than 5 %

Automated load frames are highly recommended.

ISO 130503-2 Cell for proppant crush-resistance test

The piston length shall be 88,9 mm (3 1/2 in) and the piston diameter shall be 50,8 mm (2 in) and shall have a Rockwell C hardness of 43 or better

(Rockwell C 60 preferred).

Periodic inspection for internal diameter wear indicates when the cell should be replaced.

When the internal diameter of the lower portion of the cell exceeds the designed diameter by more than 3,25 % (−10 % increase in cross-sectional area),

the cell shall be replaced;

*** Before conducting ISO 130503-2 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations