ISO 14125 – Flexural Properties of Fibre-Reinforced Plastic Composites

ISO 14125 is a test method to determine flexure properties of fiber-reinforced plastic composites.

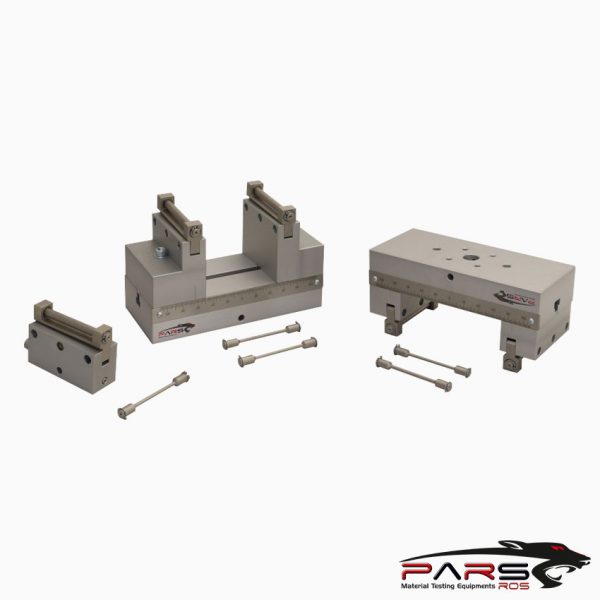

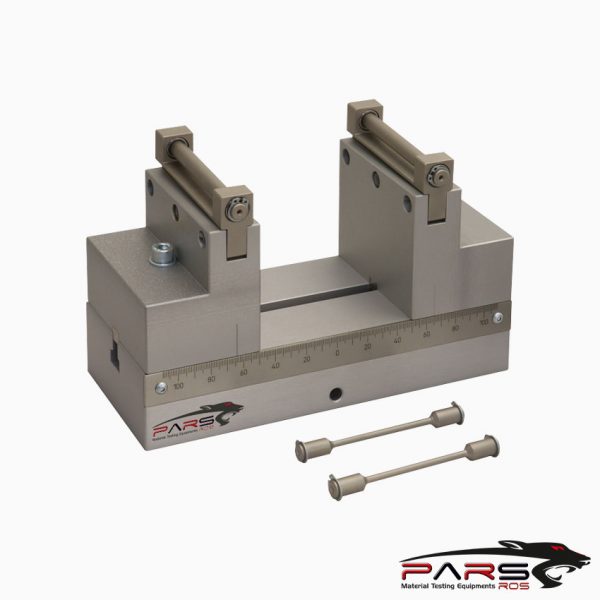

There are two methods used, Method A for a three-point flexure test and Method B for a four-point flexure test.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

ISO 14125 – Flexural Properties of Fibre-Reinforced Plastic Composites

ISO 14125 is a test method to determine flexure properties of fiber-reinforced plastic composites.

There are two methods used, Method A for a three-point flexure test and Method B for a four-point flexure test.

There are four material classes, Class I – IV, which define the specimen length, span, width, and thickness.

The standard requires deflection measurement not exceed +/- 1% error of full scale.

ISO 14125 is based on the ISO 178 standard and both utilize three point flexural testing of a freely supported bar loaded between the supports.

ISO 14125 focuses on fibre reinforced plastic compositesand has an alternative 4-point loading testing procedure, Procedure B.

The material properties recorded by following the standard are the flexural stress, flexural strain, elastic modulus in flexure and interlaminar shear modulus.

Compression-testing machine which will comply with ISO 5893 and shall be capable of maintaining speeds of (0.5 +- 20 %) mm/min to (500 +- 10 %) mm/min.

TEST METHOD

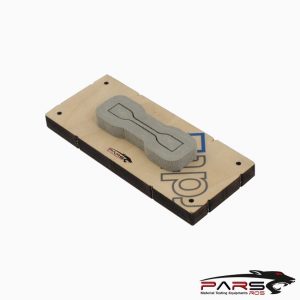

Three- or four-point flexure testing of fibre-reinforced composites per ISO 14125 is done to determine the relevant property data for material screening or quality

control.

The flexure test is performed by placing the specimen symmetrically on the support fixture that is mounted either to a servohydraulic or an electromechanical testing

machine.

The load is applied to the specimen at mid-span for three-point and equally on both loading members for four-point testing until the specimen fractures or until it

reaches a predetermined value of deformation.

The specimen deflection can be measured with a strain gage, extensometer or the load frame’s displacement transducer.

Properties that are measured include flexural strength, flexural modulus, and other aspects of the flexural stress/strain relationship.

*** This standard addresses fibre-reinforced thermosetting and thermoplastic composite materials.

*** Before conducting ISO 14125 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

*** PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations