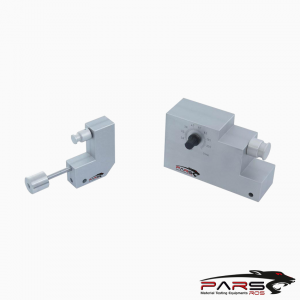

ASTM F394 Test Fixture

ASTM F394 covers the determination of the biaxial flexure strength (modulus of rupture) of thin ceramic substrates.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM F394- Standard Test Method for Biaxial Flexure Strength (Modulus of Rupture) of Ceramic Substrates

ASTM F394 covers the determination of the biaxial flexure strength (modulus of rupture) of thin ceramic substrates.

This test method is applicable to specimens in the as-fired condition or to test pieces prepared to have a certain thickness or surface finish.

This test method may be used with specimens of various thicknesses and having warpage; no limits are placed on the latter, except those mutually imposed by the

specifications agreed upon between the manufacturer and the purchaser of the substrates.

ASTM F394 / APPARATUS

Testing Machine—Any compression-type testing machine capable of providing a uniform stress rate of 200 ± 30 ksi/min (19.5 to 26.4 MPa/s) as verified by

Practices ASTM E4, and containing a load- or force-measuring cell having a resolution of 0.2 % of full scale or better on a scale appropriate to the material under test.

Test Fixture for Supporting and Loading Specimens— The support points are provided by three ball bearings 0.125 in. (3.18 mm) in diameter, positioned 120°

apart on a 1.00 ± 0.01-in. (25.2 to 25.6-mm) diameter circle.

The load is applied to the specimen center by a right circular cylinder of hardened steel having a diameter of 0.063 ± 0.001 in. (1.58 to 1.63 mm), with the end flat and

perpendicular to the axis.

The cylinder must apply the load perpendicularly (90 ± 1°) to the plane containing the tops of the support balls, and the cylinder axis must be within 0.03 in. (0.8 mm)

of the center of the support circle.

ASTM F394 / Summary of Test Method

The test specimen, a thin circular disk, rests on three symmetrically spaced points near its periphery.

It is bent in a cupping fashion by the application of force to the center of the disk through a cylindrical ram.

The force is applied to the ram at a prescribed constant rate in a compression test machine until the specimen breaks.

The breaking load, the dimensions and elastic constants of the specimen, and the radii of the support and load are used to compute the maximum tensile stress

which is at the center of the tension (convex) surface.

This is usually the point of origin of the fracture.

The computed or center stress then is the breaking stress (MOR).

This configuration eliminates premature fracture from an edge defect or anomaly

*** Before conducting ASTM F394 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply