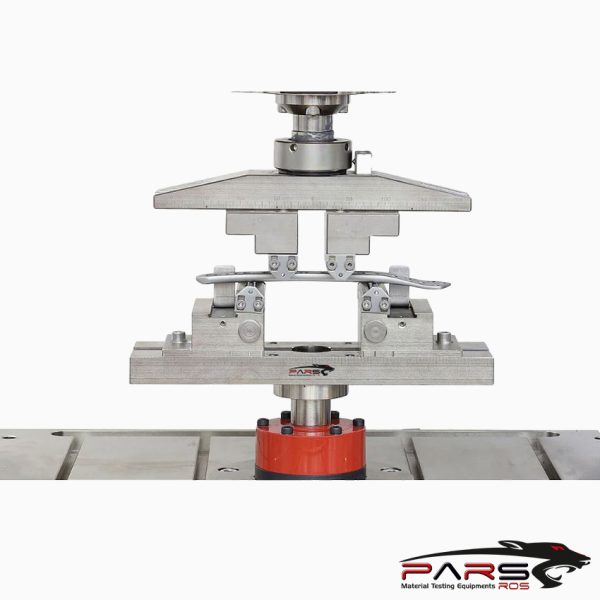

ASTM F382 Test Fixture

ASTM F382 and test method is intended to provide a comprehensive reference for metallic bone plates used in the surgical internal fixation of the skeletal system.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM F382 – Standard Specification and Test Method for Metallic Bone Plates

ASTM F382 and test method is intended to provide a comprehensive reference for metallic bone plates used in the surgical internal fixation of the skeletal system.

The standard establishes consistent methods to classify and define the geometric and performance characteristics of bone plates.

The standard also presents a catalog of standard specifications that specify material; labeling and handling requirements; and standard test methods for measuring

performance related mechanical characteristics determined to be important to the in vivo performance of bone plates.

It is not the intention of the standard to define levels of performance or case-specific clinical performance for bone plates, as insufficient knowledge is available

to predict the consequences or their use in individual patients for specific activities of daily living.

Futhermore, it is not the intention of the standard to describe or specify specific designs for bone plates used in the surgical internal fixation of the skeletal system.

This document may not be appropriate for all types of bone plates.

The user is cautioned to consider the appropriateness of the standard in view of a particular bone plate and its potential application.

This document includes the following test methods used in determining the following bone plate mechanical performance characteristics:

1- Standard Test Method for Single Cycle Bend Testing of Metallic Bone Plates—Annex A1

2-Standard Test Method for Determining the Bending Fatigue Properties Of Metallic Bone Plates—Annex A2.

ASTM F382 / STANDARD TEST METHOD FOR SINGLE CYCLE BEND TESTING OF METALLIC BONE PLATES

This test method describes methods for single cycle bend testing in order to determine the intrinsic, structural properties of metallic bone plates.

The test method measures the bending stiffness, bending structural stiffness, and bending strength of bone plates.

This test method is intended to provide a means to characterize mechanically different bone plate designs.

It is not the intention of this standard to define levels of performance for bone plates as insufficient knowledge is available to predict the consequences of the

use of particular bone plate designs.

This test method is intended to evaluate the bending strength, bending structural stiffness, or the bending stiffness of the bone plate, and may not be appropriate

for all situations.

When the structurally critical region of the bone plate is shown to be located through a non-uniform region of the bone plate (i.e., a peri-prosthetic, contoured plate),

it may be necessary to evaluate the bending strength, bending structural stiffness, or bending stiffness of this region of the bone plate using a different test method.

This is because it may not be physically possible to fit the non-uniform region between the loading rollers of a four-point bend test.

Structurally critical regions may be identified through such methods as hand calculations, Finite Element Analysis, etc.

Screw holes or other interlocking features or contoured regions may be located at the proximal or distal extremities of a bone plate, and may result in structurally

critical regions at these locations

NOTE —There is currently an ISO standard (ISO 9585—Implants for Surgery—Determination of Bending Strength and Stiffness of Bone Plates) that

is similar, but not equivalent to this test method

ASTM F382 / Apparatus

All loads shall be applied through rollers of equal diameters within the range of 6 to 12 mm.

The selected roller diameter should not be greater than the distance between two adjacent screw holes in the bone plate to be tested.

Cylindrical rollers shall be used to test flat bone plates and bone plates of curved cross-section, in which the deviation from flatness at the center of the bone plate

does not exceed w/6.

Test other bone plates using rollers of profiled form corresponding to the cross-section of the bone plate to be tested

The loading and support rollers shall be positioned as follows:

The loading rollers shall be positioned so that two screw holes will be located between the loading rollers. Record the center span distance.

The support rollers shall be located equal distances away from the adjacent loading roller so that two screw holes will be located between the adjacent loading and

support rollers.

Record the distance between the loading roller and nearest support roller.

The recommended testing configuration locates the two loading rollers at approximately the one-third points between the supporting rollers.

The applied load shall be shared equally by both loading rollers.

Machines used for the bending test shall conform to the requirements of Practice ASTM E4.

Bone plates that do not have a sufficiently long section of symmetry or do not have a section of symmetry can be attached to rigid extension segments.

The rigid extension segments can be used to effectively lengthen the bone plate so that the bone plate can be tested with the four-point bend test method

For these tests, the following requirements apply.

The rigid extension segments shall be designed so that they do not interfere with the bone plate’s deformation during the single cycle bend test.

The loading rollers shall contact the rigid extension segments of the test setup during the test.

At the completion of the single cycle bend test, the bone plate anchor shall be examined in order to determine if the indicated permanent deformation can be

related to the mechanical performance of the anchoring system.

Alternative test configurations utilized in determining the single cycle bending properties of bone plates shall be described in the test report.

*** Before conducting ASTM F382 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

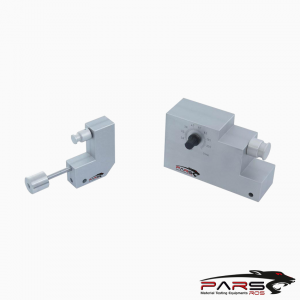

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply