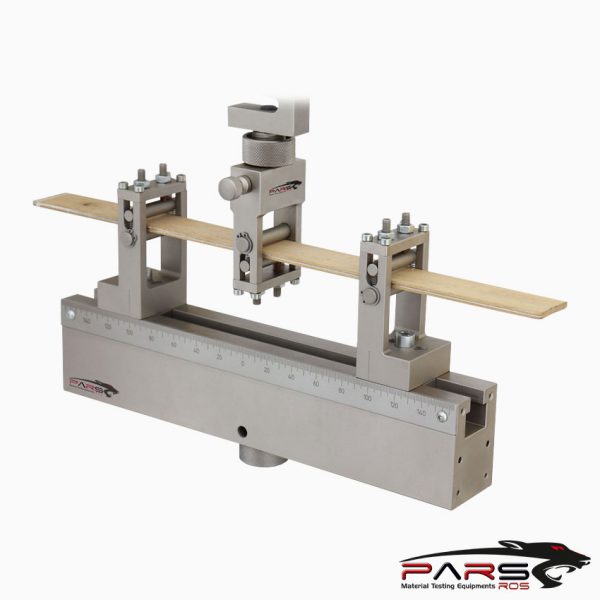

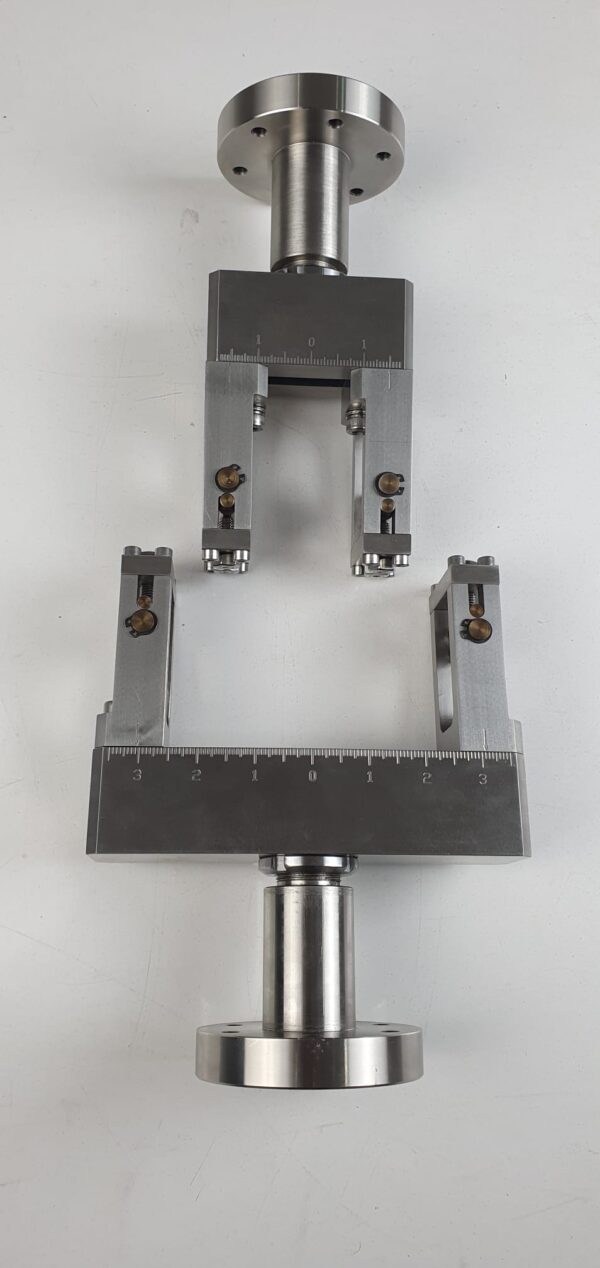

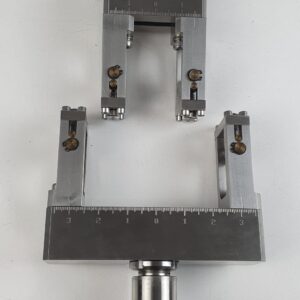

ASTM D7774 Test Fixture

ASTM D7774 – This test method covers the determination of dynamic full reversed fatigue properties of plastics in flexure.

This method is applicable to rigid and semi-rigid plastics.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D7774 – Standard Test Method for Flexural Fatigue Properties of Plastics

ASTM D7774 – This test method covers the determination of dynamic full reversed fatigue properties of plastics in flexure.

This method is applicable to rigid and semi-rigid plastics.

Stress and strain levels are below the proportional limit of the material where the strains and stresses are relatively elastic.

Three-point or four-point bending systems are used to determine these properties.

ASTM D7774 – This test method can be used with two procedures:

Procedure A, designed for materials that use three-point loading systems to determine flexural strength. Three-point loading system is used for this procedure.

Procedure B, designed for materials that use four-point loading systems to determine flexural strength. Four-point loading system is used for this procedure.

ASTM D7774 – Significance and Use

These fatigue tests are used to determine the effect of processing, surface condition, stress, and so forth, on the fatigue resistance of plastic material subjected to

flexural stress for relatively large numbers of cycles.

The results can also be used as a guide for the selection of plastic materials for service under conditions of repeated flexural stress.

Properties can vary with specimen depth and test frequency. Test frequency can be 1-25 Hz but it is recommended that a frequency of 5 Hz or less be used.

Material response in fatigue is not identical for all plastics.

If a plastic does not exhibit an elastic region, where strain is reversible, plastic deformation will occur during fatigue testing, causing the amplitude of the

programmed load or deformation to change during testing.

In this situation, caution shall be taken when using the results for design as they are generally not indicative of the true fatigue properties of the material.

*** Before conducting ASTM D7774 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Referenced Documents

ASTM Standards

ASTM D618 Practice for Conditioning Plastics for Testing

ASTM D638 Test Method for Tensile Properties of Plastics

ASTM D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

ASTM D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

ASTM D883 Terminology Relating to Plastics

ASTM D1505 Test Method for Density of Plastics by the Density-Gradient Technique

ASTM D2839 Practice for Use of a Melt Index Strand for Determining Density of Polyethylene

ASTM D3479/D3479M Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials

ASTM D4883 Test Method for Density of Polyethylene by the Ultrasound Technique

ASTM D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

ASTM D6272 Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E83 Practice for Verification and Classification of Extensometer Systems

ASTM E1942 Guide for Evaluating Data Acquisition Systems Used in Cyclic Fatigue and Fracture Mechanics Testing

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations