ASTM D6272 – Flexural Properties of Unreinforced and Reinforced Plastics

ASTM D6272 – This test method covers the determination of flexural properties of unreinforced and reinforced plastics, including high-modulus composites and electrical

insulating materials in the form of rectangular bars molded directly or cut from sheets, plates, or molded shapes.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D6272 – Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials by Four-Point Bending

ASTM D6272 – This test method covers the determination of flexural properties of unreinforced and reinforced plastics, including high-modulus composites and

electrical insulating materials in the form of rectangular bars molded directly or cut from sheets, plates, or molded shapes.

This test method is generally applicable to rigid and semirigid materials.

However, flexural strength cannot be determined for those materials that do not break or that do not fail in the outer fibers.

This test method utilizes a four point loading system applied to a simply supported beam.

ASTM D6272 – This test method describes two procedures (Procedure A and Procedure B), the selection of which depends on the behavior of the sample to be tested

as explained below:

Procedure A, designed principally for materials that break at comparatively small deflections.

It shall be used for measurement of flexural properties, particularly flexural modulus, unless the material specification states otherwise.

Procedure B, designed particularly for those materials that undergo large deflections during testing. It is suitable for measurement of flexural strength.

*** Before conducting ASTM D6272 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

Significance and Use

Flexural properties determined by this test method are especially useful for quality control and specification purposes.

This test method is recommended for those materials that do not fail within the strain limits imposed by Test Method D790.

The major difference between four point and three point bending modes is the location of the maximum bending moment and maximum axial fiber stress.

In four point bending the maximum axial fiber stress is uniformly distributed between the loading noses.

In three point bending the maximum axial fiber stress is located immediately under the loading nose.

Flexural properties vary with specimen depth, temperature, atmospheric conditions, and the difference in rate of straining specified in Procedures A and B.

ASTM D6272 – Test Procedure

For the four point flexural test, the specimen lies on a span and stress is uniformly distributed between the loading noses.

There are two procedures within the ASTM D6272 method.

Procedure A is followed for materials with smaller deflection and for measuring modulus.

Procedure B is followed for materials with larger deflections and used for measuring strength.

Materials specifications may also be followed. Support span-to-depth ratios are dependent on material type and thickness.

Load span to support span can be a ratio of 1 to 2 or 1 to 3.

Elevated or Reduced Temperature Test Procedure

A thermal chamber is installed on the Universal Testing Machine.

The chamber is designed to allow the test mounts from the base and crossheadof the Tester to pass through the top and bottom of the chamber.

Standard test fixtures are installed inside the chamber, and testing is conducted inside the controlled thermal environment the same as it would be at

ambient temperature.

The chamber has internal electric heaters for elevated temperatures and uses external carbon dioxide gas as a coolant for reduced temperatures.

Specimen size

ASTM D6272 outlines specimen sizes for specimens with thickness less than 1/16 inch, thickness greater than 1/16 inch, laminate thermosetting sheet, molded materials

and high-strength reinforced composites.

Five specimens are typically tested. For anisotropic materials, flatwise and edgewise specimens may be tested.

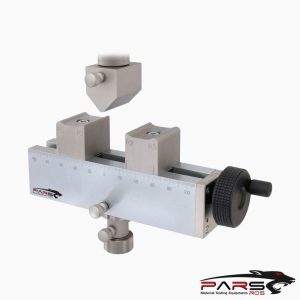

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Referenced Documents

ASTM Standards

ASTM D618 Practice for Conditioning Plastics for Testing

ASTM D638 Test Method for Tensile Properties of Plastics

ASTM D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

ASTM D883 Terminology Relating to Plastics

ASTM D4000 Classification System for Specifying Plastic Materials

ASTM D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E83 Practice for Verification and Classification of Extensometer Systems

ASTM E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

Reviews (0)

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply