ASTM D575 – Standard Test Methods for Rubber Properties in Compression

ASTM D575 – This test method cover two test procedures for determining the compression-deflection characteristics of rubber compounds other than

those usually classified as hard rubber and sponge rubber.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D575 – Standard Test Methods for Rubber Properties in Compression

ASTM D575 – Rubber Compression Test

ASTM D575 – This test method cover two test procedures for determining the compression-deflection characteristics of rubber compounds other than

those usually classified as hard rubber and sponge rubber.

Significance and Use

This test method is useful in comparing stiffness of rubber materials in compression.

They can be used by rubber technologists to aid in development of materials for compressive applications.

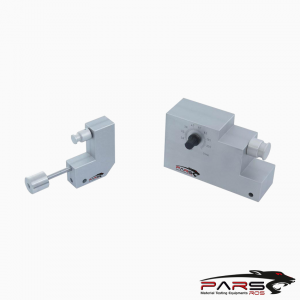

The compressive properties of rubber are tested using compression platens.

Sandpaper may be used in between the platens and the sample in order to reduce the occurance of slippage.

For this test, the rubber sample is compressed to a pre-specified deflection percentage.

The platens must be larger than the sample and also must be rigidily fixed.

The standard clevis pin and jam nut mechanism is sufficient to lock the platens. A deflectomer may be attached directly to the platens for high precision testing.

ASTM D575 Test Method A – Compression Test of Specified Deflection for Rubber

ASTM D575 (D-575) test method A is a procedure for determining the compression-deflection of rubber compounds (except hard rubber and sponge rubber).

ASTM D575 is useful in comparing stiffness of rubber materials in compression.

They can be used by rubber technologists to aid in development of materials for compressive applications.

ASTM D575 test method A is a compression test in which the force required to cause a specified deflection is determined.

Deflection is the change in thickness of the specimen upon application of a compressive force.

After measuring the thickness of the test specimen, place the specimen between the platens of the testing machine.

Place sheets of sandpaper between the rubber surfaces and the testing machine platens.

The sandpaper resists lateral slippage of the rubber at the contact surfaces and should be slightly larger than the specimen.

Apply the force to precisely produce a deflection rate of 12 mm/min (0.5 in./min) until the specified deflection is reached,after which release the force immediately

at the same rate. Repeat the loading cycle a second time.

Apply the force a third time until the specified deflection is again reached.

Read and record the force required.

The machine may be stopped at intervals of 5 % deflection during the third application and the force recorded for each deflection so that a stress-strain curve

may be drawn.

Deflection percentage is based on the thickness of the specimen prior to the first force application.

ASTM D575 Test Method B – Compression Test at a Force for Rubber

ASTM D575 (D-575) method B is useful in comparing stiffness of rubber materials in compression.

ASTM D575 method B covers procedures for determining the compression-deflection of rubber compounds.

ASTM standards can be used by rubber technologists to aid in development of materials for compressive applications.

This test constitutes only one kind of compression stiffness measurement.

Test method B is a compression test in which the specified mass or compressive force is placed on the specimen and the resulting deflection is measured

and recorded.

Deflection is the change in thickness of the specimen upon application of a compressive force.

Apply a specified minor jog force for a period long enough to adjust the deflection gage, after which apply the full test force for 3 seconds.

Read the deflection on the dial gage at the end of the 3 second period.

The reading shall not include any deflection caused by the jog force.

Calculate the percent deflection on the basis of the original thickness of the specimen. Report the median of values taken from three specimens

Referenced Documents

ASTM Standards

ASTM D3183 Practice for RubberPreparation of Pieces for Test Purposes from Products

ASTM D3767 Practice for Rubber–Measurement of Dimensions

ASTM D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

ASTM E4 Practices for Force Verification of Testing Machines

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that are

accurate and repeatable.

Reviews (0)

TECHNICAL SPECIFICATIONS

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply