ASTM D1781 – Standard Test Method for Climbing Drum Peel for Adhesives

ASTM D1781 -This test method is used to compare adhesion between flexible and rigid adherends, or between flexible facing of a sandwich structure and its core.

Comparisons of adhesives and processes are only applicable when test specimens and conditions are the same.

The peel resistance may indicate degree of cure for relatively brittle adhesives.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

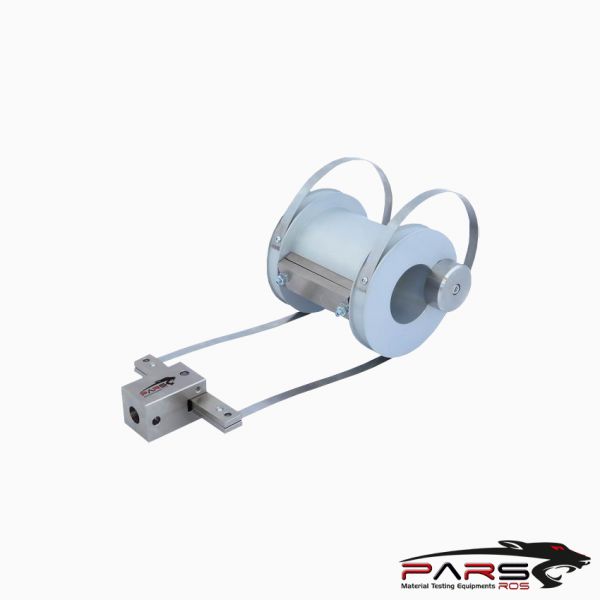

ASTM D1781 – Standard Test Method for Climbing Drum Peel for Adhesives

ASTM D1781 -This test method is used to compare adhesion between flexible and rigid adherends, or between flexible facing of a sandwich structure and its core.

Comparisons of adhesives and processes are only applicable when test specimens and conditions are the same.

The peel resistance may indicate degree of cure for relatively brittle adhesives.

The Climbing Drum Peel testing fixture is designed to test adhesives as they relate to the flexibility of their backing material.

Pressure Sensitive Adhesives (PSA) and other materials such as fabrics and foams are converted together to make a combination product.

ASTM D1781 – Specimen Size

Six specimens tested. Samples need to be thick enough not to bend during test.

For laminates, 25 mm [1 in] wide between saw kerfs by at least 254 mm [10 in].

For adhesives in sandwich construction, 76 mm [3 in] wide between saw kerfs by at least 305 mm [12 in], including ~25 mm [1 in] overhang of one facing at each end.

For adhesives in bonding metal-faced sandwich construction, a facing of clad aluminum alloy meeting Specification

B29, Alloy 2024-T3, 0.51 mm [0.020 in] thick with a core 12.7 mm [0.5 in] thick, or comparably flexible material is required.

ASTM D1781 – Test Procedure

The setup of this test requires the adhesive skin to overhang the board or backing material by a few inches.

The skin or tape must be wrapped around the drum and then secured in the clamp.

Once the drum is secured the board is then pulled up at constant speed and the drum “climbs” along the backing material, delaminating it at a certain force.

The width of the sample adhesive is the most important when specifying a new climbing drum fixture.

The grips of a Universal Test Machine are initiated at a specified grip separation significant enough to roll the drum upward.

The standard speed is 25.40 ± 2.54 mm/min [1.00 ± 0.10 in/min].

Like most peel strength tests, the final analysis involves taking an average of the data after removing the beginning and end parts.

Similar Specifications

ASTM D3167 – Floating Roller Peel Test

Referenced Documents

ASTM Standards

B209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

D907 Terminology of Adhesives

E4 Practices for Force Verification of Testing Machines

**** PARSROS offers several types of grips and fixtures which will enable you to perform a variety of

lap shear tests that are accurate and repeatable.

| Product Description | EN2243 DIN53295 ( diameter 100 )

ASTM-D1781 (diameter 102 mm ) |

| Adapter / Coupling | 15.9 mm cup with 8 mm pin

Further connections on request |

| Max Sample width | 80mm |

| Max load | 5kN |

| Weight | 3kg |

| Material | Alu Steel |

| Surface | Eloxat Nickel |

| Standards | ASTM-D1781 EN2243 DIN53295 |

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations