ASTM C1211 Test Fixture

ASTM C1211 covers determination of the flexural strength of advanced ceramics at elevated temperatures.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM C1211- Standard Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures

ASTM C1211 covers determination of the flexural strength of advanced ceramics at elevated temperatures.

Four-point-1/4-point and three-point loadings with prescribed spans are the standard

Rectangular specimens of prescribed cross-section are used with specified features in prescribed specimen-fixture combinations.

Test specimens may be 3 by 4 by 45 to 50 mm in size that are tested on 40-mm outer span four-point or three-point fixtures.

Alternatively, test specimens and fixture spans half or twice these sizes may be used.

The test method permits testing of machined or as-fired test specimens.

Several options for machining preparation are included: application matched machining, customary procedures, or a specified standard procedure.

ASTM C1211 describes the apparatus, specimen requirements, test procedure, calculations, and reporting requirements.

The test method is applicable to monolithic or particulate- or whisker-reinforced ceramics.

It may also be used for glasses.

*** It is not applicable to continuous fiber-reinforced ceramic composites.

ASTM C1211 / Significance and Use

ASTM C1211 may be used for material development, quality control, characterization, and design data generation purposes.

This test method is intended to be used with ceramics whose flexural strength is ∼50 MPa (∼7 ksi) or greater.

The flexure stress is computed based on simple beam theory, with assumptions that the material is isotropic and homogeneous, the moduli of elasticity in tension

and compression are identical, and the material is linearly elastic.

The average grain size should be no greater than 1/50 of the beam thickness.

The homogeneity and isotropy assumptions in the test method rule out the use of it for continuous fiber-reinforced composites for which Test Method ASTM C1341

is more appropriate.

The flexural strength of a group of test specimens is influenced by several parameters associated with the test procedure.

Such factors include the testing rate, test environment, specimen size, specimen preparation, and test fixtures.

Specimen and fixture sizes were chosen to provide a balance between the practical configurations and resulting errors as discussed in Test Method C1161

Specific fixture and specimen configurations were designated in order to permit the ready comparison of data without the need for Weibull size scaling.

The flexural strength of a ceramic material is dependent on both its inherent resistance to fracture and the size and severity of flaws.

Variations in these cause a natural scatter in test results for a sample of test specimens. Fractographic analysis of fracture surfaces, although beyond the scope of

this test method, is highly recommended for all purposes, especially if the data will be used

ASTM C1211 determines the flexural strength at elevated temperature and ambient environmental conditions at a nominal, moderately fast testing rate.

The flexural strength under these conditions may or may not necessarily be the inert flexural strength.

Flexure strength at elevated temperature may be strongly dependent on testing rate, a consequence of creep, stress corrosion, or slow crack growth.

If the purpose of the test is to measure the inert flexural strength, then extra precautions are required and faster testing rates may be necessary.

Note : Many ceramics are susceptible to either environmentally assisted slow crack growth or thermally activated slow crack growth.

Oxide ceramics, glasses, glass ceramics, and ceramics containing boundary phase glass are particularly susceptible to slow crack growth.

Time-dependent effects that are caused by environmental factors (for example, water as humidity in air) may be minimized through the use of inert testing

atmosphere such as dry nitrogen gas or vacuum.

Alternatively, testing rates faster than specified in this standard may be used if the goal is to measure the inert strength.

Thermally activated slow crack growth may occur at elevated temperature even in inert atmospheres.

Testing rates faster than specified in this standard should be used if the goal is to measure the inert flexural strength.

On the other hand, many ceramics such as boron carbide, silicon carbide, aluminum nitride, and many silicon nitrides have no sensitivity to slow crack growth

at room or moderately elevated temperatures and for such materials, the flexural strength measured under laboratory ambient conditions at the nominal testing

rate is the inert flexural strength.

The three-point test configuration exposes only a very small portion of the specimen to the maximum stress.

Therefore, three-point flexural strengths are likely to be much greater than four-point flexural strengths.

Three-point flexure has some advantages. It uses simpler test fixtures, it is easier to adapt to high temperature, and it is sometimes helpful in Weibull

statistical studies.

However, four-point flexure is preferred and recommended for most characterization purposes.

The three-point test configuration exposes only a very small portion of the specimen to the maximum stress.

Therefore, three-point flexural strengths are likely to be much greater than four-point flexural strengths.

Three-point flexure has some advantages. It uses simpler test fixtures, it is easier to adapt to high temperature, and it is sometimes helpful in Weibull

statistical studies.

However, four-point flexure is preferred and recommended for most characterization purposes.

ASTM C1211 / Apparatus

Testing machine provided that uniform rates of direct loading can be maintained.

The force measuring system shall be free of initial lag at the loading rates used and shall be equipped with a means for retaining readout of the maximum force

as well as a force-time or force-deflection record.

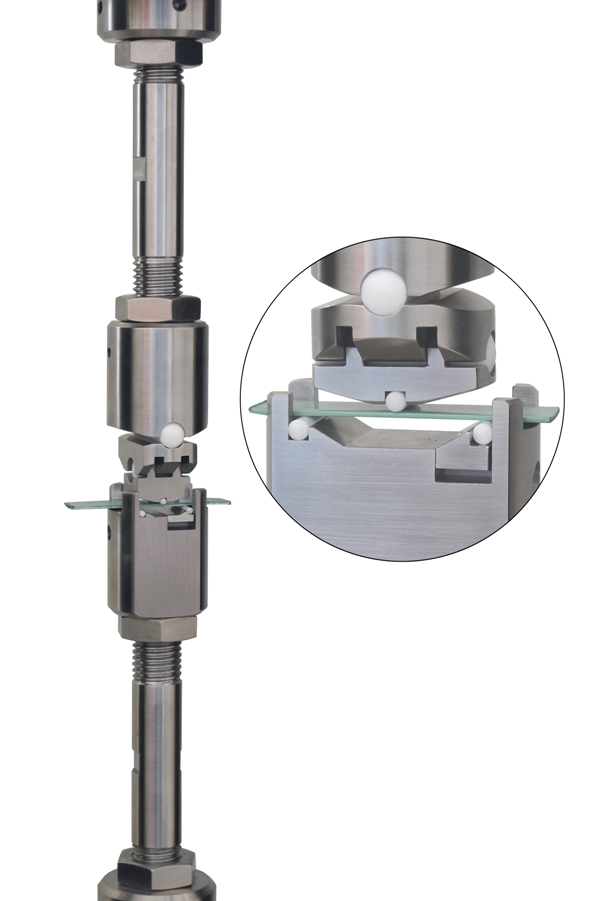

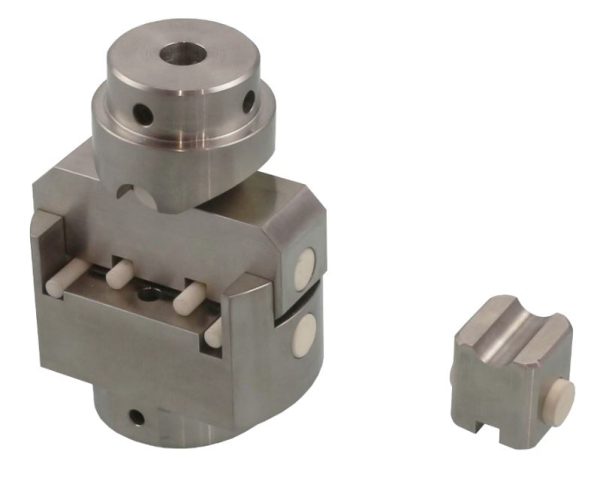

ASTM C1211 / Four-Point Flexure Four-Point-1⁄4-Point Fixtures having support spans

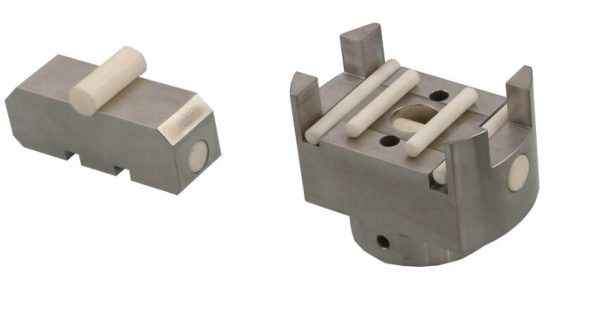

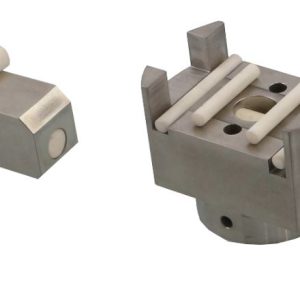

ASTM C1211 /Three-Point Flexure Three-Point Fixtures, having a support span Bearings, Three- and four-point flexure.

Cylindrical bearings shall be used for support of thetest specimen and for load application.

The cylinders may bemade of a ceramic with an elastic modulus between 200 and 400 GPa (30 to 60 × 106 psi) and a flexural strength no less than

275 MPa (»40 ksi).

The loading cylinders must remain elastic (and have no plastic deformation) over the load and temperature ranges used, and they must not react chemically

with or contaminate the test specimen.

The test fixture shall also be made of a ceramic that is resistant to permanent deformation.

The bearing cylinder diameter shall be approximately 1.5 times the beam depth of the test specimen size

The bearing cylinders shall be positioned carefully such that the spans are accurate to within 60.10 mm.

The load application bearing for the three-point configurations shall be positioned midway between the support bearings within 60.10 mm.

The load application (inner) bearings for the four-point configurations shall be centered with respect to the support (outer) bearings within 60.10 mm.

The bearing cylinders shall be free to rotate in order torelieve frictional constraints (with the exception of the middleload bearing in three-point flexure,

which need not rotate).

Note : Two inner bearings shall be parallel to each other to within 0.015 mm over their length.

The two outer bearings shall be parallel to each other to within 0.015 mm over their length.

The inner bearings shall be supported independently of the outer bearings.

All four bearings shall rest uniformly and evenly across the specimen surfaces.

The fixture shall be designed to apply equal load to all four bearings.

ASTM C1211 / Fully Articulating Four-Point Fixture

Specimens that are as-fired, heat treated, or oxidized often have slight twists or unevenness.

Specimens that do not meet the parallelism requirements shall be tested in a fully articulating fixture Well-machined specimens may also be tested in

fully articulating fixtures.

All four bearings shall be free to roll. One bearing need not articulate.

The other three bearings shall articulate to match the specimen’s surface.

All four bearings shall rest uniformly and evenly across the specimen surfaces.

The fixture shall apply equal load to all four bearings.

ASTM C1211 / Semi-Articulated Three-Point Fixture—Specimens prepared in accordance with the parallelism requirements may be tested in a

semi-articulating fixture.

The middle bearing shall be fixed and not free to roll.

The two outer bearings shall be parallel to each other to within 0.015 mm over their length.

The two outer bearings shall articulate together to match the specimen surface, or the middle bearing shall articulate to match the specimen surface.

All three bearings shall rest uniformly and evenly across the specimen surface.

The fixture shall be designed to apply equal load to the two outer bearings.

ASTM C1211 / Fully Articulated Three-Point Flexure—Specimens that do not meet the parallelism requirements shall be tested in a fully

articulating fixture

Well-machined specimens may also be tested in fully articulating fixtures.

The two support (outer) bearings shall be free to roll outwards.

The middle bearing shall not roll. Any two of the bearings shall be capable of articulating to match the specimen surface.

All three bearings shall rest uniformly and evenly across the specimen surface.

The fixture shall be designed to apply equal load to the two outer bearings.

SASTM C1211 / ystem Compliance—The compliance of the load train shall be characterized for the loading range used and the testing temperature.

The load train and fixtures shall be sufficiently rigid so that at least 80 % of the crosshead motion is transmitted to the actual test specimens.

The load train and fixtures shall not permanently deform during testing.

It is not necessary to check the system compliance for every test sequence, provided that it has been characterized previously for the identical setup.

ditions used.

The fixture shall be oxidation resistant if the testing is performed in air.

Referenced Documents

ASTM C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

ASTM C1239 Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

ASTM C1322 Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

ASTM C1341 Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites

ASTM C1368 Test Method for Determination of Slow Crack Growth Parameters of Advanced Ceramics by Constant Stress Rate Strength Testing at

Ambient Temperature

ASTM C1465 Test Method for Determination of Slow Crack Growth Parameters of Advanced Ceramics by Constant Stress-Rate Flexural Testing at

Elevated Temperatures

ASTM E4 Practices for Force Calibration and Verification of Test- ing Machines

ASTM E220 Test Method for Calibration of Thermocouples By Comparison Techniques

ASTM E230 Specification for Temperature-Electromotive Force (emf) Tables for Standardized Thermocouples

*** Before conducting ASTM C1211 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply