TAPPI T 549 Test Fixture

TAPPI T 549 describes a horizontal plane procedure for the determination of the coefficient of static and kinetic friction of paper measured when sliding against itself.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

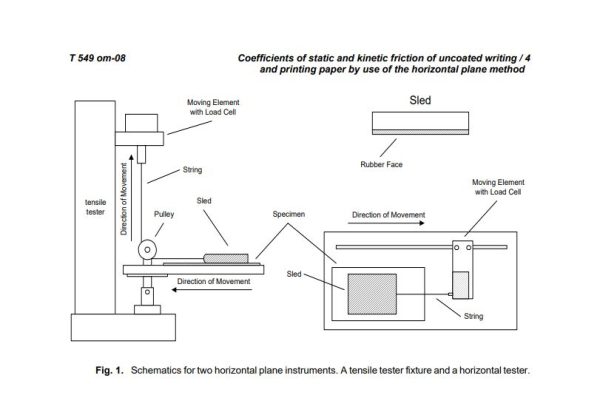

TAPPI T 549 Coefficients of Static and Kinetic Friction of Uncoated Writing and Printing Paper by Use of the Horizontal Plane Method (Reaffirmation of T 549 om-08) (no changes from Draft 1)

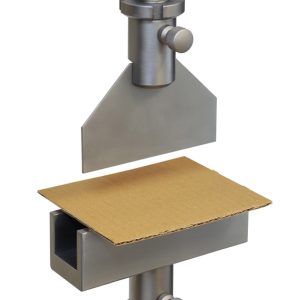

TAPPI T 549 describes a horizontal plane procedure for the determination of the coefficient of static and kinetic friction of paper measured when sliding against itself.

The horizontal instrument requires some means of movement of the specimen in relation to the surface upon which it rests.

The coefficient of friction (COF) is measured directly from the resistance to tangential motion and the applied weight pressing two pieces of paper together.

Static COF relates to the force required to initiate movement between two surfaces while kinetic COF relates to the force required to cause continuation of the

movement at uniform speed.

The determinations of COF for packaging materials is described in TAPPI T 815 “Coefficient of Static Friction (Slide Angle) of Packaging and Packaging Materials

(Including Shipping Sack Papers, Corrugated and Solid Fiberboard) (Inclined Plane Method).”

In the method for testing packaging materials, the force measurement is often made on the third slip, while in this method the determination is made on the first slip.

TAPPI T 549 – Apparatus

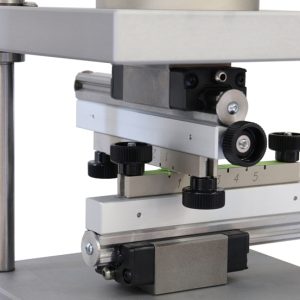

Horizontal plane and supporting base, a horizontal plane surface of a smooth, incompressible material – metal, hardwood, plate glass or plastic, having a width

at least 25 mm (1 in.) wider than the specimen sled (see 6.2). The plane is mounted on a supporting base provided with means of leveling in two directions.

A constant rate-of-motion tester, as described in TAPPI T 494, has also been found suitable. If this type of tester is used, the horizontal plane and supporting base are

one and the same.

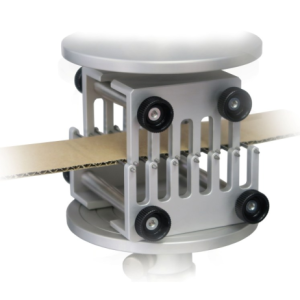

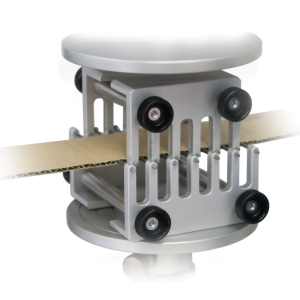

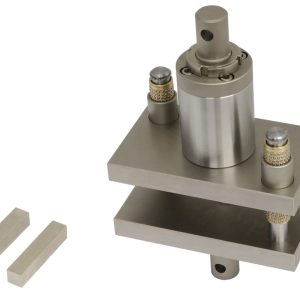

Specimen sled, a sled or specimen block made of an incompressible 63.5-mm (2.5-in.) square metal block weighing 200 ± 5 g has been found satisfactory.

The precision statement is based on a sled of that size.

The lower surface of the specimen block shall be backed with a compressible backing made from a sheet of closed cell neoprene cellular rubber, with a thickness

between 1.5 mm and 3.0 mm.

The backing shall have a uniform thickness and shall be replaced if its edges become worn or its surface becomes damaged.

A means for clamping the specimen to the sled may be provided, but it is not necessary if the lower surface is faced with 3-mm (0.12-in.) thick backing.

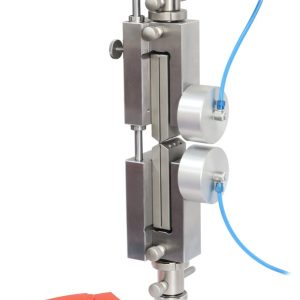

A means for fastening the sled to the force measuring device, such as a wire cable or nylon filament line, is required.

Take care in selecting a wire cable or nylon filament line to make certain that its ability to stretch does not interfere with the measurement of force.

The sled may be directly connected to the load cell.

Mechanical power unit, means for moving the specimen sled horizontally along the plane surface, or the plane surface under the specimen sled at a uniform

speed of 150 ± 30 mm/min (0.5 ± 0.1 ft/min).

A constant rate-ofmotion tester equipped with a load cell in its upper crosshead and a constant rate-of-motion lower crosshead has been found satisfactory

(T 494).

Force measuring device, means for measuring the force required to move or restrain the specimen sled to the nearest 5 gf (0.01 lbf).

A force gauge or the load cell of a constant rate-of-motion tester have both been found suitable.

*** Before conducting TAPPI T 549 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply