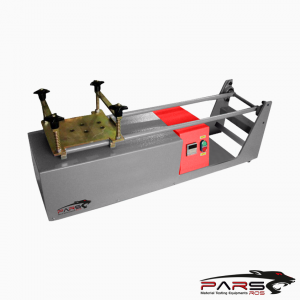

Freezing and Thawing Test Chamber

Freezing and Thawing tests due to high resistance which are used in road construction applications and accepted as the main criteria are extremely important.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code | Product Descripton |

| PRS-CMDT400 | Freezing and Thawing Test Chamber |

Freezing and Thawing Test Chamber

In addition to the strength of concrete, the other most important feature is its durabilitywhich is related to the building type and environmental conditions.

Freezing and Thawing tests due to high resistance which are used in road construction applications and accepted as the main criteria are extremely important.

Features of Freezing and Thawing Test Chamber

The device works at 380 volts / 50hz.

It has the capacity and competence to provide the 80 ± 3 oC water temperature specified in TS EN 1344.

The device control system is capable of connecting to a computer. (LCD screen is 7” in size, it changes optionally)

Temperature steps depending on the test cycle and times can be selected according to the desired standard, in the range of 30 C / -30 C, with an accuracy of ±1 C.

The water tank is made of 400~ liter polyurethane plastic material.

In the water dissolving step, the time of taking the water, waiting and discharging can be defined separately.

During the test cycles, the water is pumped from the water tank to the reservoir and reintroduced into the water tank automatically by the device.

The test chamber of the device works with a single cover and shock absorber support.

There is a fixed thermocouple (thermal couple) to measure the ambient temperature of the test chamber.

There are two independent (moving) thermocouples to measure the internal or surface temperatures of the samples.

Water levels are controlled with the help of sensors.

Durable and long-lasting water motors are used to ensure the circulation of water at an equal and homogeneous temperature from the water tank to the test chamber

from the test chamber to the water tank.

There are 6 wheels attached to the sub-chassis to ensure the movement of the device on the ground.

The device has 1 mains water inlet and a drain tap for water change.

The chamber water temperature (80 ± 3 oC) defined in the TS EN 1344 standard will be provided and cooling can be achieved gradually with the addition of mains water.

Again, a uniformly distributed water spray system is used on the sample at the times and capacity described in the same standard.

Device ; It provides freezing and thawing conditions, temperature values and calibration conditions depending on TS EN 539-2, TS EN 491, TS EN 1344 and

TS EN ISO 10545-12 standards.

Device control can be accessed remotely, starting, stopping, monitoring etc. features such as

The device can appeal to many sectors with its suitability for universal use.

The external dimensions of the device are 100x230x125~ cm and 416 stainless steel.

The inner test chamber of the device is 80x75x65 cm in size (400 liters) and is made of 304 stainless steel.