ASTM C364 Test Fixture

ASTM C364 covers the compressive properties of structural sandwich construction in a direction parallel to the sandwich facing plane.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

ASTM C364 Standard Test Method for Edgewise Compressive Strength of Sandwich Constructions

ASTM C364 covers the compressive properties of structural sandwich construction in a direction parallel to the sandwich facing plane.

Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous

bonding surfaces (such as honeycomb).

Summary of Test Method

ASTM C364 consists of subjecting a sandwich panel to monotonically increasing compressive force parallel to theplane of its faces.

The force is transmitted to the panel through either clamped or bonded end supports.

Stress and strength are reported in terms of the nominal cross-sectional area of the two facesheets, rather than total sandwich panel thickness, although alternate

stress calculations may be optionally specified.

The only acceptable failure modes for edgewise compressive strength of sandwich constructions are those occurring away from the supported ends.

The sandwich column, no matter how short, usually is subjected to a buckling type of failure unless the facings are so thick that they themselves are in the short

column class.

The failure of the facings manifests itself by wrinkling of the facing, in which the core deforms to the wavy shape of the facings; by dimpling of the facings into the

honeycomb cells; by bending of the sandwich, resulting in crimping near the ends as a result of shear failure of the core; or by failure in the facing-to-core bond

and associated facesheet buckling.

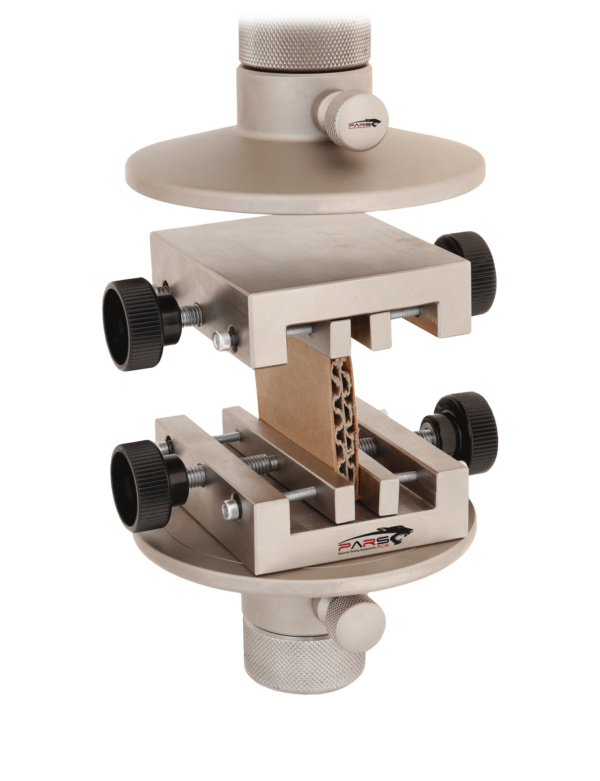

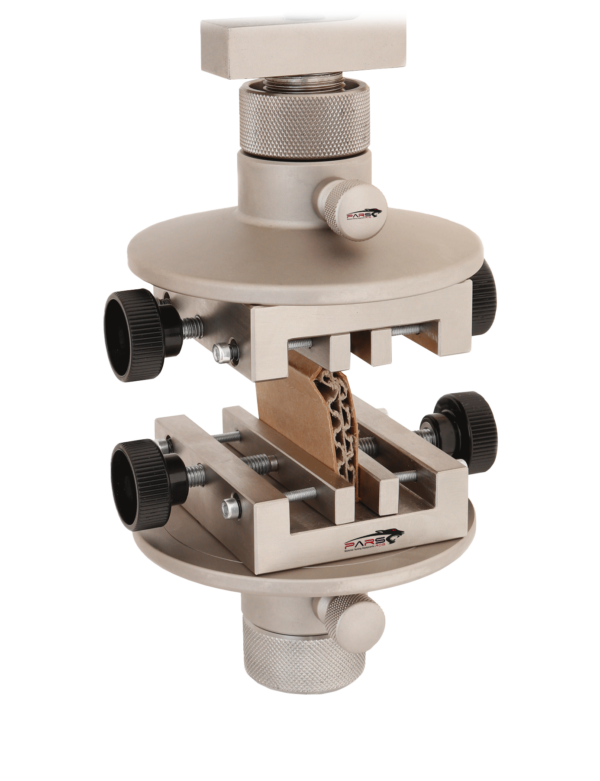

ASTM C364 Apparatus

Test Fixtures

Spherical Bearing Block, preferably of the suspended,self-aligning type.

Lateral End Supports—Via clamps made of rectangular steel bars fastened together so as to clamp the specimen lightly between them the cross-sectional

dimensions of each of these bars shall be not less than 6 mm [0.25 in.]

fitting the specimen snugly into a lengthwise slot in a round steel bar, where such bars shall have a diameter not less than the thickness of the sandwich plus 6 mm

[0.25 in.], and are suitably retained on the spherical bearing block surfaces; or casting the ends of the specimens in resin or other suitable molding material.

The cast ends of the specimen should be ground flat and parallel, meeting or exceeding the specimen end tolerances

Testing Machine—The testing machine shall be in accordance with Practices E 4 and shall satisfy the following requirements:

Testing Machine Configuration—The testing machine shall have both an essentially stationary head and a movable head.

Drive Mechanism—The testing machine drive mechanism shall be capable of imparting to the movable head a controlled velocity with respect to the stationary

head.

The velocity of the movable head shall be capable of being regulated

*** Before conducting ASTM C364 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations